I was wondering if anyone had any suggestions for removing radial caps from a circuit board when they are both soldered and glued on without damaging the board. Example: Egnator amp

Announcement

Collapse

No announcement yet.

Removing glued on capacitors from circuit board?

Collapse

X

-

I haven't seen the inside of an Egnater (not Egnator) in person. None of the images I looked at show any glue. Is it that hot melt anti vibration goop? Silicone? Either way, what you need to do is remove all the solder first. Obviously a de soldering station is best followed by a de soldering pen followed by what I use. A bulb sucker and braid. But it all works. Remove all the solder and Exacto the goop. Or, if the goop isn't on any traces you can just de solder and rip the caps out "Take two placebos, works twice as well." Enzo

"Take two placebos, works twice as well." Enzo

"Now get off my lawn with your silicooties and boom-chucka speakers and computers masquerading as amplifiers" Justin Thomas

"If you're not interested in opinions and the experience of others, why even start a thread?

You can't just expect consent." Helmholtz

-

PITA, def. I use an exacto blade to score the glue around the cap, being careful not to cut the PCB. I insert a prying tool into the gap between the cap and the board, in-line with the cap's two leads. I heat the pin closest to the pry tool on the reverse side of the board. This lets me lever that side of the cap slightly, maybe a millimeter, letting the solder cool while still applying leverage. Then switch sides. In this way, I can "walk" the cap out of the board in three or four attempts.

Comment

-

If it is silicone, I slit it with an Xacto, if it is hot melt, I spray it with freeze spray, and the glue is then easily shattered with a tool of some sort.Education is what you're left with after you have forgotten what you have learned.

Comment

-

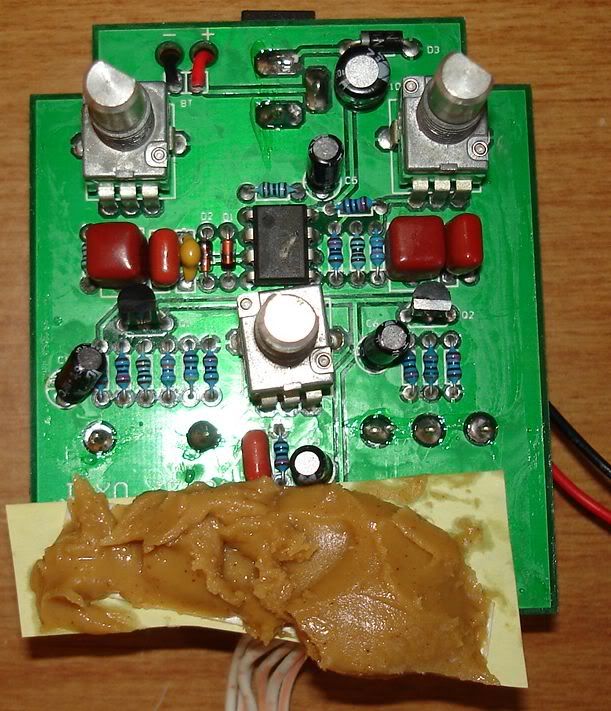

Want goop?:

U$50000 Dumble, including "Tasty Countertop Formica Boards"[tm]

what if you run out of "Blue Goop"[tm] ?

Just a little shovel, 10 minutes in the street, and neighbourhood doggies supply you with a free substitute.

And .... think about it: many try to remove classic Goop, but not many will put their fingers inside *that* , so after all it's as effective or better:

Juan Manuel Fahey

Juan Manuel Fahey

Comment

-

And modeling amps would use modeling clay, right? You can get it in any color you like, and you can reconfigure it however you want, and it all leaves a nasty greasy mess on your hands when you're done playing with it...

Justin"Wow it's red! That doesn't look like the standard Marshall red. It's more like hooker lipstick/clown nose/poodle pecker red." - Chuck H. -

"Of course that means playing **LOUD** , best but useless solution to modern sissy snowflake players." - J.M. Fahey -

"All I ever managed to do with that amp was... kill small rodents within a 50 yard radius of my practice building." - Tone Meister -

Comment

-

-

I had to download that one... wow, "goop" is a verb, and a technical procedure...

Justin"Wow it's red! That doesn't look like the standard Marshall red. It's more like hooker lipstick/clown nose/poodle pecker red." - Chuck H. -

"Of course that means playing **LOUD** , best but useless solution to modern sissy snowflake players." - J.M. Fahey -

"All I ever managed to do with that amp was... kill small rodents within a 50 yard radius of my practice building." - Tone Meister -

Comment

-

Rivera does that, except the glue is only between the cap (tight to the board) and the board, you CAN'T GET TO IT to do anything to it. They seriously did not consider maintenance/repair when they decided to do that. I had to remove one and thought the board was going to break. I tried heat, etc, nothing made that crap let go and I couldn't get any kind of blade directly on it.

Comment

-

That's why I suggested removing as much solder as possible. Rather than heating and prying. It's really not that hard. You can usually remove enough solder that the cap can just be lifted out. Or only one lead still adheres a little. One touch with the iron and it pops out. Minimum damage. I can usually pull it off with my bulb sucker and braid. Sometimes it helps clean out more solder if you suck once, reflow the joint and then suck it out again."Take two placebos, works twice as well." Enzo

"Now get off my lawn with your silicooties and boom-chucka speakers and computers masquerading as amplifiers" Justin Thomas

"If you're not interested in opinions and the experience of others, why even start a thread?

You can't just expect consent." Helmholtz

Comment

Comment