Mine has also seen use to lower the temperature on a toaster oven to make superb meringues.

Announcement

Collapse

No announcement yet.

Nice inexpensive variac found on-line

Collapse

X

-

Variacs are uncommon here in Argentina, simply because average people does not have an use for them, so very small market for them, BUT the main remaining use is in Theatrical/Opera light control/fading in-out.

First because they have been available since forever, how do you think Opera stage lights (which are *incredibly* creative) were controlled in, say, 1910 or 1920?

No Electronics of any kind available way back then, let alone Triacs, SCRs or even Mercury filled funny tubes (which are impressive on their own, Iīll add a YT Video just for fun).

Second because Opera Lighting operator were trained with and got used to them.

An Italian friend of mine was trained so nowhere less than in Milanīs Scala Opera Theater and then moved yo Argentina where he was understandably successful until today, and he sweared by his "klunky/outmoded" Variac based system.

He simply "could not work" with standard modern dimmers.

Then my ex partner designed and built for him a system with the corrected control curve so output follows a linear *voltage* equivalence of pot rotation, same as Variac output does, instead of the linear *phase* which is the standard way.

Only "SS Variac" he would use.

Sadly the circuits are lost, my ex partner passed away and circuit boards live inside black epoxy bricks.

Oh well.Juan Manuel Fahey

Comment

-

Pete Biltoft from Vintage Vibe uses one in conjunction with his customized crock pot to wax pot the pickups he makes.Originally posted by Mick Bailey View PostMine has also seen use to lower the temperature on a toaster oven to make superb meringues.

Vintage Vibe Guitar Pickups: Pete Biltoft

Steve A.The Blue Guitar

www.blueguitar.org

Some recordings:

https://soundcloud.com/sssteeve/sets...e-blue-guitar/

.

Comment

-

Rather than a variac, my old high school had stage lighting that was dimmed using large 240v rheostats. There was a thick resistance winding on a ceramic former and the bakelite slider knob moved a carbon brush mounted on a bronze leaf spring. It looked like a gigantic fader from a mixing desk, and had a slot that you could see the winding through. Parents these days would be horrified.

Comment

-

I had the honor/privilege in late 60's school years of running the lighting & sound for the county summer music school which took place at Montclair NJ High. The old lighting board was up a ladder and in a cage about 10 feet off stage deck level. Big old variac style faders with stick handles on them. But the worst part was a patch bay of quarter-inch plugs in a steel bin at the bottom of the board. The good part was you could program color & lamp groups with the patches. The not so good part was live AC on those patch plugs. Can't tell you how many shocks I got. Learned quickly to patch one-handed, while not leaning on the control panel. "Parents these days would be horrified." To say the least . . .Originally posted by Mick Bailey View PostRather than a variac, my old high school had stage lighting that was dimmed using large 240v rheostats. There was a thick resistance winding on a ceramic former and the bakelite slider knob moved a carbon brush mounted on a bronze leaf spring. It looked like a gigantic fader from a mixing desk, and had a slot that you could see the winding through. Parents these days would be horrified.This isn't the future I signed up for.

Comment

-

I did some stage crew work in junior high and high school. Our big light board was variacs and rheostats. All the lights had those heavy pin connectors. I don't know if they still use those anywhere. I suspect they went over to Hubble or some such.Education is what you're left with after you have forgotten what you have learned.

Comment

-

An analog meter is an excellent idea. One big advantage of the analog meter over a digital one is that the analog meter allows you to easily see the rate of change of the current draw. You can see trends, suspicious accelerations and pulses of the current draw. This type of information is easily obscured by a digital meter’s sampling rate and automatic range switching. I feel that a current meter is essential for test bench work.Originally posted by SoulFetish View Post…I plan installing a an analog current meter when bringing up the voltage on suspected shorted equipment and digital V/A meters for accurate operating measurements.

As Enzo commented, “Serious applications probably already have current monitoring.” A simple variable transformer has many uses but a dedicated test bench variable AC supply would be something like the Staco Model E1010VA AC Variable Transformer with integrated Voltmeter & Ammeter pictured here.Originally posted by SoulFetish View PostBut, I don’t understand why every variac does [not] come standard with a current meter included. Isn’t that the most common use? To test for fault current?

For anyone needing a test bench “Variac” these are still available for around $100 if you are patient in your search. The analog voltmeter and dual range ammeter are nice large easy to read indicators.

Cheers,

Tom

Comment

-

Or you can even make a similar unit. Basically a box wrapped around your variac, with meters on the panel. Wiring is simple.

I have one of these, and it is very handy to use with a variac or other testing:

https://www.ebay.com/i/132449537078?chn=ps

Better view:

https://people.ohio.edu/postr/bapix/RWattmtr.htm

Robinair makes a number of similar models, you can usually find them cheap. I think they are aimed at the HVAC and appliance repair crowd mainly.Education is what you're left with after you have forgotten what you have learned.

Comment

-

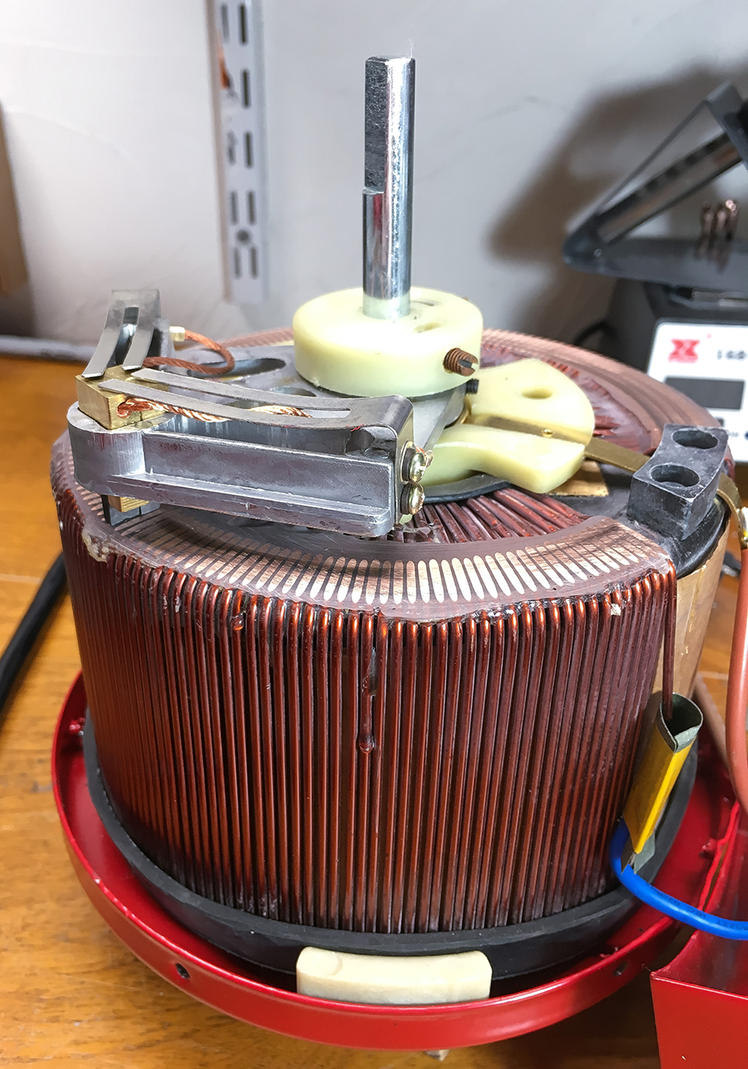

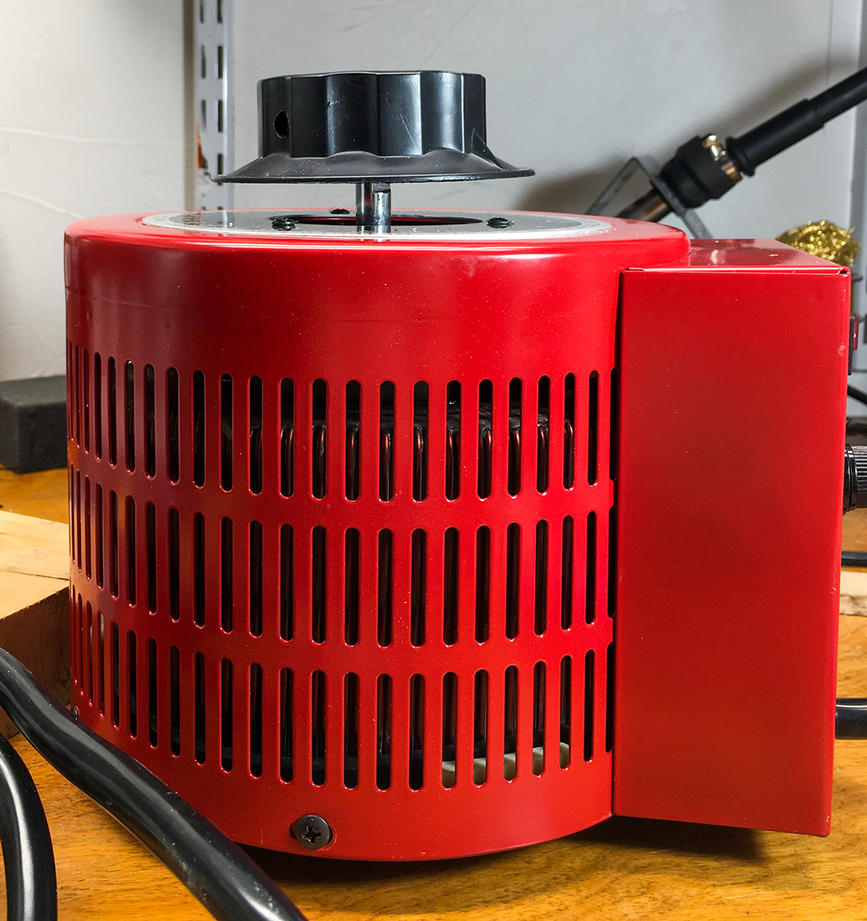

quick rundown on 2kVA variac from CircuitSpecialist

My Variac arrived yesterday and I had a chance to take a look and snap some photos. It's a good thing it got here yesterday, 'cause we're in the throws of a white-out blizzard today.

Some positive initial thoughts on the quality–keeping in mind this unit cost was $99 shipped:

•It was well packed in form-fitting foam inserts inside a small box. Then packed surrounded on all 4 sides by packing peanuts and enclosed in a larger box. They did a great job packing it for shipment.

•It looks like they used quality materials in the construction and pretty solid assembly as far as mechanical strength. I think Mick was wondering if they used copper windings.

•The Enclosure also has a nice finish and looks like they provided plenty of venting for air flow.

•Replacement brushes are available.

Here are some issues I have with the unit:

•First and foremost, the chassis-earth connection was done with a flat washer on top(over) the painted finished chassis, relying on the physical connection of an oxide coated screw into a couple of threads of the thin enclosure for electrical continuity. This is a huge issue with me. IMO, this is one thing which you just should not, CANNOT get wrong. Even if the paint was conductive (which it ISN'T), the paint would not be better than clean contact between the two metals. Now, even after installing a star washer to "bite" through the layer of paint between the terminal and enclosure, I measured continuity with a resistance of 2.1 ohms between the variac's panel outlet and chassis. In the event of a 20A fault current to trip the breaker, this would result in a Potential difference of 42V RMS to exist on the chassis.

This is unacceptable, but easily fixed.

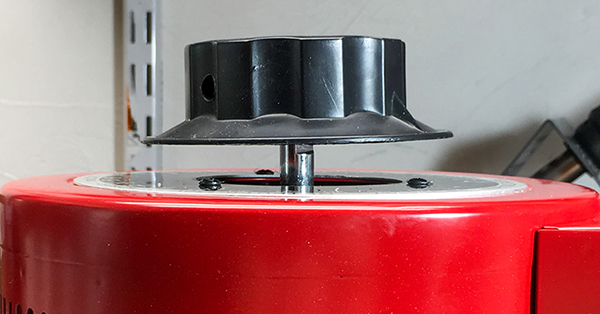

The only other issue I have with the unit, is the runout in knob and control shaft. Meaning, there's drift in the level of concentricity when rotating the dial. I'm probably being a little "nitpicky" with this one.

Thats my honest write up on this so far. I'm curious to here what you guys think!

******************************************************** **********************************

I should probably let it go, but.... this does annoy the shit out of me though aaaarrrrgg!

aaaarrrrgg!

it's like

think I'm being obsessive?If I have a 50% chance of guessing the right answer, I guess wrong 80% of the time.

Comment

-

>>> The only other issue I have with the unit, is the runout in knob and control shaft. Meaning, there's drift in the level of concentricity when rotating the dial. I'm probably being a little "nitpicky" with this one.<<<

In the picture it looks to me that the knob is mounted a little bit crooked on the shaft.

SteveThe Blue Guitar

www.blueguitar.org

Some recordings:

https://soundcloud.com/sssteeve/sets...e-blue-guitar/

.

Comment

-

It is a little bit. There are two set screws on the knob. I have a dial indicator, and will probably monkey with it and see if I can improve it.Originally posted by Steve A. View Post>>> The only other issue I have with the unit, is the runout in knob and control shaft. Meaning, there's drift in the level of concentricity when rotating the dial. I'm probably being a little "nitpicky" with this one.<<<

In the picture it looks to me that the knob is mounted a little bit crooked on the shaft.

SteveIf I have a 50% chance of guessing the right answer, I guess wrong 80% of the time.

Comment

-

See, that would make sense to have the set screw aligned with the flatted shaft. But the knob is a D-type insert, with the set screws about 120˚ offset.Originally posted by Enzo View PostLooks to me that the shaft is flatted, and the knob set screw is not aligned with the flat.If I have a 50% chance of guessing the right answer, I guess wrong 80% of the time.

Comment

Comment