Hi there,

I'm toying with designing a 'widget' in my spare time (actually, it's just my take on an existing theme!), but what's becoming quite apparent is that after I 'dip my toe in the marketplace water', that if it sells, I'm going to need a better way of making/sourcing bobbins!

At the minute I'm using a CNC machine to cut my own bobbins from acrylic sheet...it works, but it's very slow.

Now, while I'm reasonably adept at the techie side of things, I'm clueless as to the 'plastics' manafacturing process & just wondered if you knowledgeable fellas on here could give me some good input/leads?

The bobbin I require is the same basic shape as a Stratocaster single coil ...but where it differs from that is that the bobbin is only 6mm deep - nothing exists like this, so I need to establish a way of having these made cheaply!

What would be the best path? ...& what would the manafacturer need from me? (DXF file, a prototype etc)

What type of cost per unit would I be facing (for say a 500 piece first run)

I'm toying with designing a 'widget' in my spare time (actually, it's just my take on an existing theme!), but what's becoming quite apparent is that after I 'dip my toe in the marketplace water', that if it sells, I'm going to need a better way of making/sourcing bobbins!

At the minute I'm using a CNC machine to cut my own bobbins from acrylic sheet...it works, but it's very slow.

Now, while I'm reasonably adept at the techie side of things, I'm clueless as to the 'plastics' manafacturing process & just wondered if you knowledgeable fellas on here could give me some good input/leads?

The bobbin I require is the same basic shape as a Stratocaster single coil ...but where it differs from that is that the bobbin is only 6mm deep - nothing exists like this, so I need to establish a way of having these made cheaply!

What would be the best path? ...& what would the manafacturer need from me? (DXF file, a prototype etc)

What type of cost per unit would I be facing (for say a 500 piece first run)

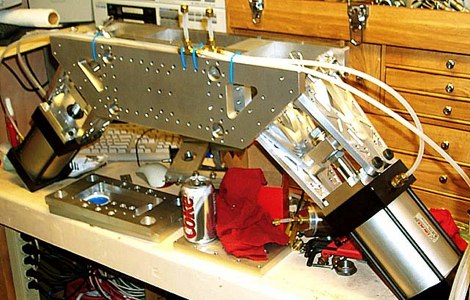

you can always build your own injection molder check out rhe hack a day link

you can always build your own injection molder check out rhe hack a day link

Comment