Originally posted by Chadheckler1

View Post

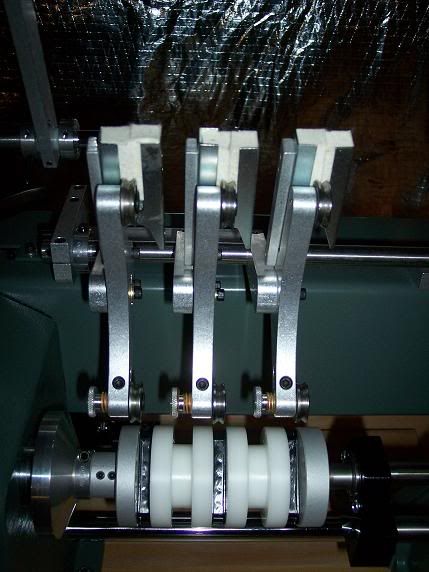

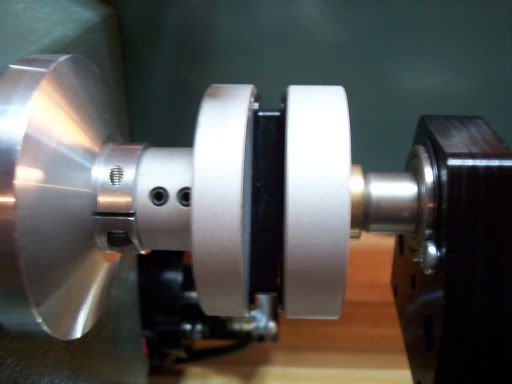

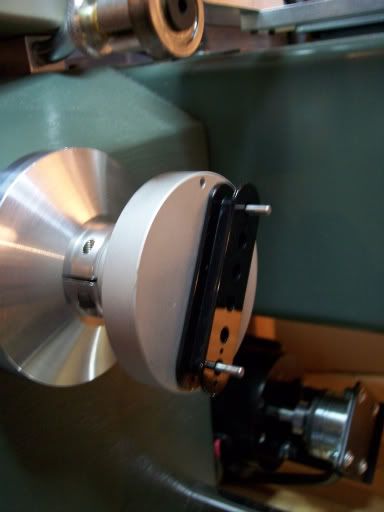

My tooling interlocks with one another and it helps with any saging issues. I can wind 3 bobbins at a time, but for now I only wind one at a time. You may also have to deal with wobbling when the tooling and bobbins are too spread out and then your bobbins wouldn't be consistantly accurate.

Bottom line is that it can be done, but you may run into some snags based on your equipment.

To add, most commercial winders are setup with a traverse, tailstock, controller,, etc. The Leesona is a different animal. Because each peice of tooling that is holding the bobbin is a separate componant... when it's all linked together.....the pieces will have the tendency to sag as opposed to remaining straight like one solid piece of wood in a lathe.

Comment