I've got a Fender Stage 112SE that I've had since new (1996). I've never had it opened up/modded/repaired until recently. I just replaced the clean channel volume pot with an audio taper pot. While I was in there, I touched up a few cracked/sketchy solder joints.

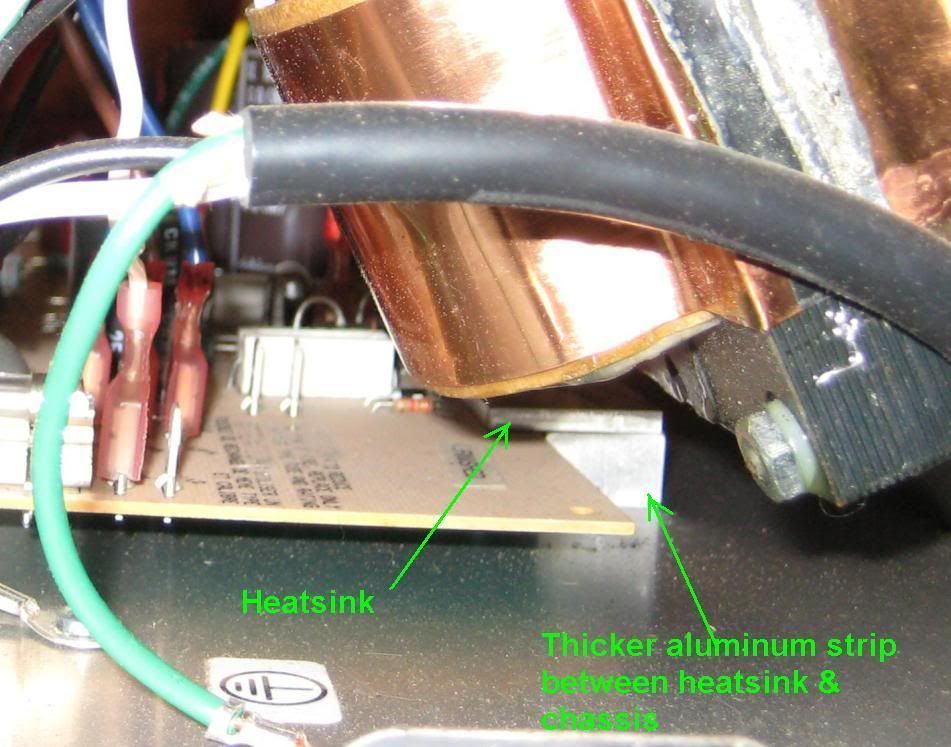

Before I mounted the chassis back in the cab, I turned it on to make sure everything worked OK. I hadn't yet connected the external speaker jack back up yet. I also hadn't reinstalled all the screws (only 2/7) that attach the back of the board, through the thick aluminum strip (heatsink) , to the chassis. The amp turned on fine, so I plugged my guitar in just to check if it played fine. It did. There was a slight "shhhhh" static noise as it sit there with the guitar plugged in, but got silent when the guitar cable was removed. I thought this may me due to the external speaker jack not being connected, so I stuck it in its hole and the amp made a pop noise (similar to touching the end of a guitar cable while it's plugged into an amp) so I pulled it back out and left it alone.

Then, I decided, I would check for any loose components while the amp was on by lightly touching (with a plastic mechanical pencil) some caps, resistors and diodes on the side to see if any seemed loose and made noise. I got some slight noise from a few, but then I would touch the same one again and would get nothing. Then I apparently touched the wrong thing because the fuse blew, and I smelled a slight burning smell coming from somewhere.

I pulled the board back out to check for any obvious damage, but visually found none. I went and got some more fuses at Radio Shack. I re-assembled the amp completely and replaced the fuse, I turned it on. I was greeted by a hum for a split second before the fuse blew in a flash of greenish light. I double-checked all my connections and tried again. Same thing. Then I thought I may have connected my RCA cables to the reverb pan wrong, so I reversed them. Fuse still blew.

Now I am at a loss. I pulled the board out again to look for damage, scorch marks, anything out of the ordinary. I couldn't find anything.

I have the schematic and a digital multimeter, but I'm not sure where to start with the troubleshooting.

Thanks,

Mike

Before I mounted the chassis back in the cab, I turned it on to make sure everything worked OK. I hadn't yet connected the external speaker jack back up yet. I also hadn't reinstalled all the screws (only 2/7) that attach the back of the board, through the thick aluminum strip (heatsink) , to the chassis. The amp turned on fine, so I plugged my guitar in just to check if it played fine. It did. There was a slight "shhhhh" static noise as it sit there with the guitar plugged in, but got silent when the guitar cable was removed. I thought this may me due to the external speaker jack not being connected, so I stuck it in its hole and the amp made a pop noise (similar to touching the end of a guitar cable while it's plugged into an amp) so I pulled it back out and left it alone.

Then, I decided, I would check for any loose components while the amp was on by lightly touching (with a plastic mechanical pencil) some caps, resistors and diodes on the side to see if any seemed loose and made noise. I got some slight noise from a few, but then I would touch the same one again and would get nothing. Then I apparently touched the wrong thing because the fuse blew, and I smelled a slight burning smell coming from somewhere.

I pulled the board back out to check for any obvious damage, but visually found none. I went and got some more fuses at Radio Shack. I re-assembled the amp completely and replaced the fuse, I turned it on. I was greeted by a hum for a split second before the fuse blew in a flash of greenish light. I double-checked all my connections and tried again. Same thing. Then I thought I may have connected my RCA cables to the reverb pan wrong, so I reversed them. Fuse still blew.

Now I am at a loss. I pulled the board out again to look for damage, scorch marks, anything out of the ordinary. I couldn't find anything.

I have the schematic and a digital multimeter, but I'm not sure where to start with the troubleshooting.

Thanks,

Mike

Comment