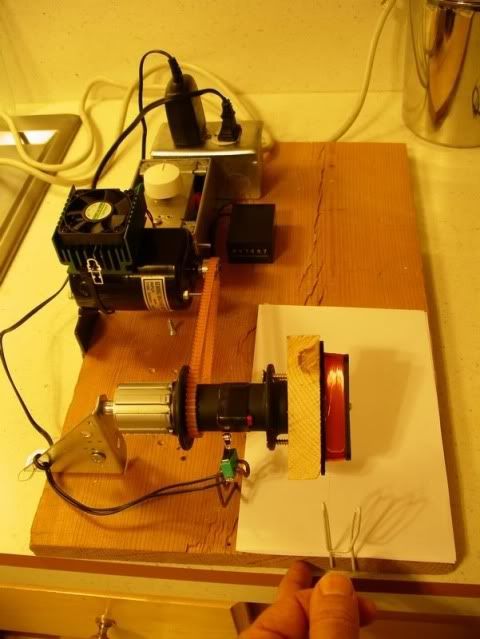

John....fantastic looking machine! I may do the same at some point....I have not wound anything on my machine yet, but Ive heard others say anywhere from 700-1200rpms it will stay accurate....It sounds like others have also had the best luck with rare earth magnets.

-Erin

-Erin

Comment