Hi there. This nice old GK MB150e came in with a fuse blown, the complaint being it started humming then the fuse went. Two of the outputs were shorted. All other semiconductors beeped on the diode tester but I changed all the outputs (TIP35c/TIP36c) and the three drivers (TIP29c/TIP30c). I set the bias ( by watching the current draw 'knee' like Enzo taught me, and doing the fine adjustment for 0.6vDC on the output bases) having brought it up slow on the variac and it was fine at first, but the fault remained - after a short while it hummed (I presume stuck to a rail), the current draw shot up, then shorted just one output transistor - Q783 - before I could switch it off. Replaced all outputs and drivers all over again but this time also put a new heat transfer sheet (the grey stuff) under the outputs, just because I didn't the first time and you never know, that stuff has caught me out before. Up on the variac again and it ran fine for a while then the depressing thing that happens, happened - it hummed again, though my finger was on the switch and I switched it off quick and saved the outputs from shorting, though not I guess from stress. Turned it on again normally, with the switch, and with heart in mouth (actually I just thought, f*ck it, in for a penny), and it is running happily here beside me, but of course I can't really trust it enough to give back to the customer. I played it quite hard for a while - all still good.

What would you do to ensure stability?

What would you do to ensure stability?

. And in truth I don't know the cause.

. And in truth I don't know the cause.

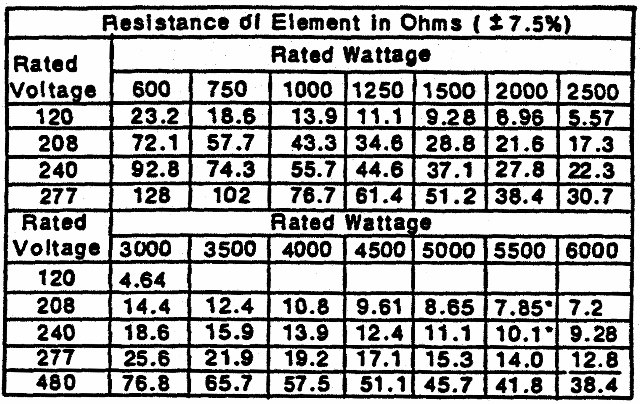

) meaning 50 to 250mA per device meaning 2.25W to 11.25W per device or 45W idle dissipation counting all 4.

) meaning 50 to 250mA per device meaning 2.25W to 11.25W per device or 45W idle dissipation counting all 4.

Comment