You guys can ignore this thread for a while. I'll post progress on my Vox JMI-era AC15 OA-031 circuit build incrementally as work progresses, so it will be a long while before there is anything interesting to see in here. The end goal is a mostly-period-correct repro of a 1963-64 fawn 1x12 combo with copper faceplate, 12" Celestial Alnico Blue speaker, ClassicTone transformers and choke, and NCM licensed replacement cabinet. Current total cost of all parts is just under $1500. The most expensive single item is the ~$500 combo cabinet.

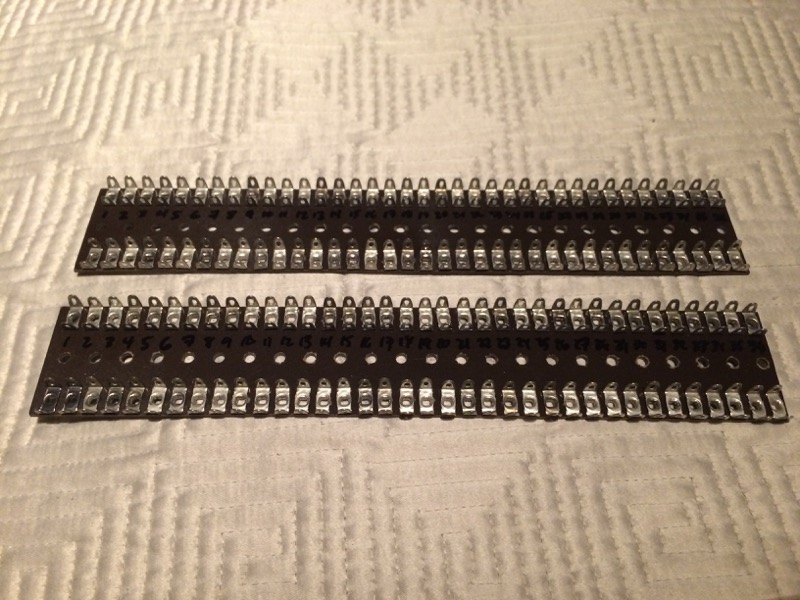

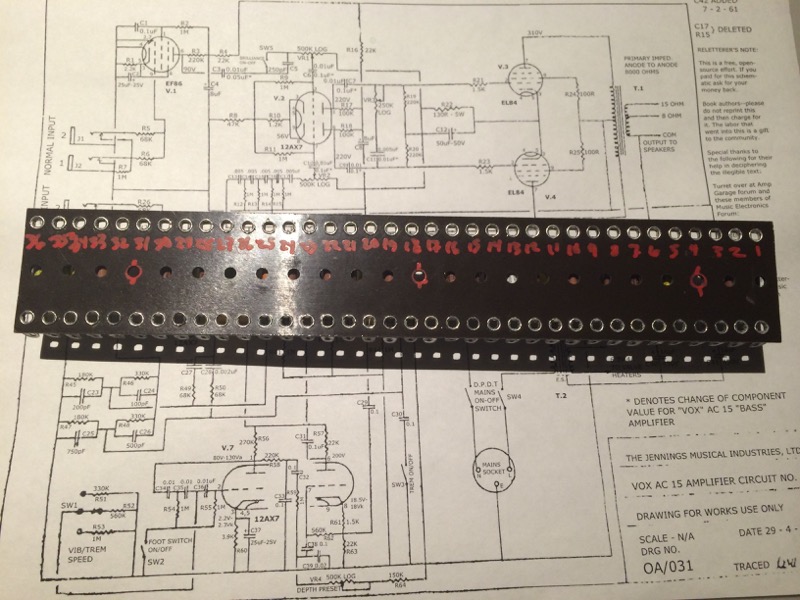

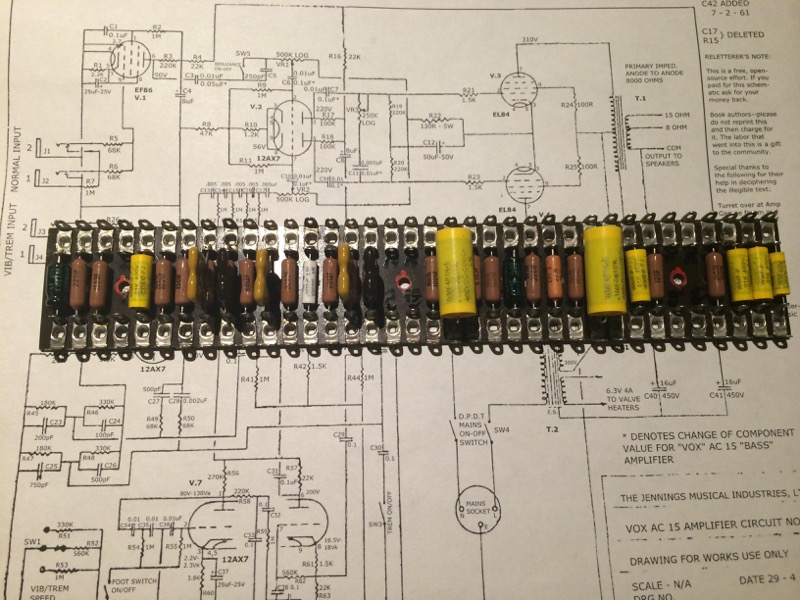

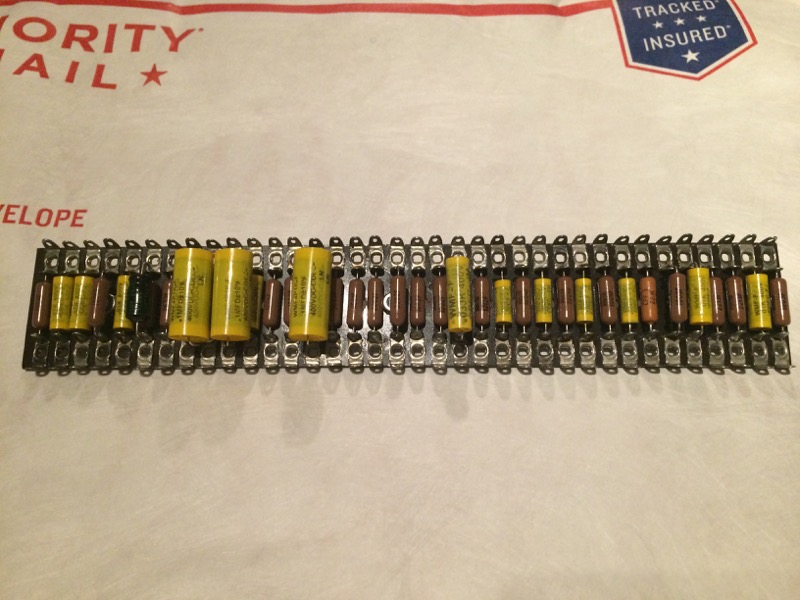

To start, here are photos of tagstrip boards made in England from paxolin. They are made and sold on eBay by Steve in the UK (expensive, as this is the only source out there) and started out as 42-lug (for AC30s). I cut them down to 36-lug with a Japanese-style fine-tooth pull saw (better fine motor control with a pull saw) and started populating them with Dale 1/2W mil spec resistors and CDE WMF-series 400V foil-and-polyester-film capacitors as well as CDE 500V silver mica capacitors and a handful of Sprague Atom electrolytic capacitors.

A couple of capacitor values were not available for sale in the CDE WMF-series, so I had to use CDE's Mallory 150 series instead or step up to 630V WMF-series (white colored instead of yellow). I don't think these substitutions are in the signal path, but I didn't check closely.

The lower tagstrip board (further away from the controls) is raised by 3/8" standoffs (installed). The upper board will eventually get 3/16" standoffs when they arrive. I'll put the remaining components on that board after installing the standoffs.

To start, here are photos of tagstrip boards made in England from paxolin. They are made and sold on eBay by Steve in the UK (expensive, as this is the only source out there) and started out as 42-lug (for AC30s). I cut them down to 36-lug with a Japanese-style fine-tooth pull saw (better fine motor control with a pull saw) and started populating them with Dale 1/2W mil spec resistors and CDE WMF-series 400V foil-and-polyester-film capacitors as well as CDE 500V silver mica capacitors and a handful of Sprague Atom electrolytic capacitors.

A couple of capacitor values were not available for sale in the CDE WMF-series, so I had to use CDE's Mallory 150 series instead or step up to 630V WMF-series (white colored instead of yellow). I don't think these substitutions are in the signal path, but I didn't check closely.

The lower tagstrip board (further away from the controls) is raised by 3/8" standoffs (installed). The upper board will eventually get 3/16" standoffs when they arrive. I'll put the remaining components on that board after installing the standoffs.

Comment