Hi,

Noob here, so any help is appreciated. This is the first time I've posted. I've been lurking around here for a while now.

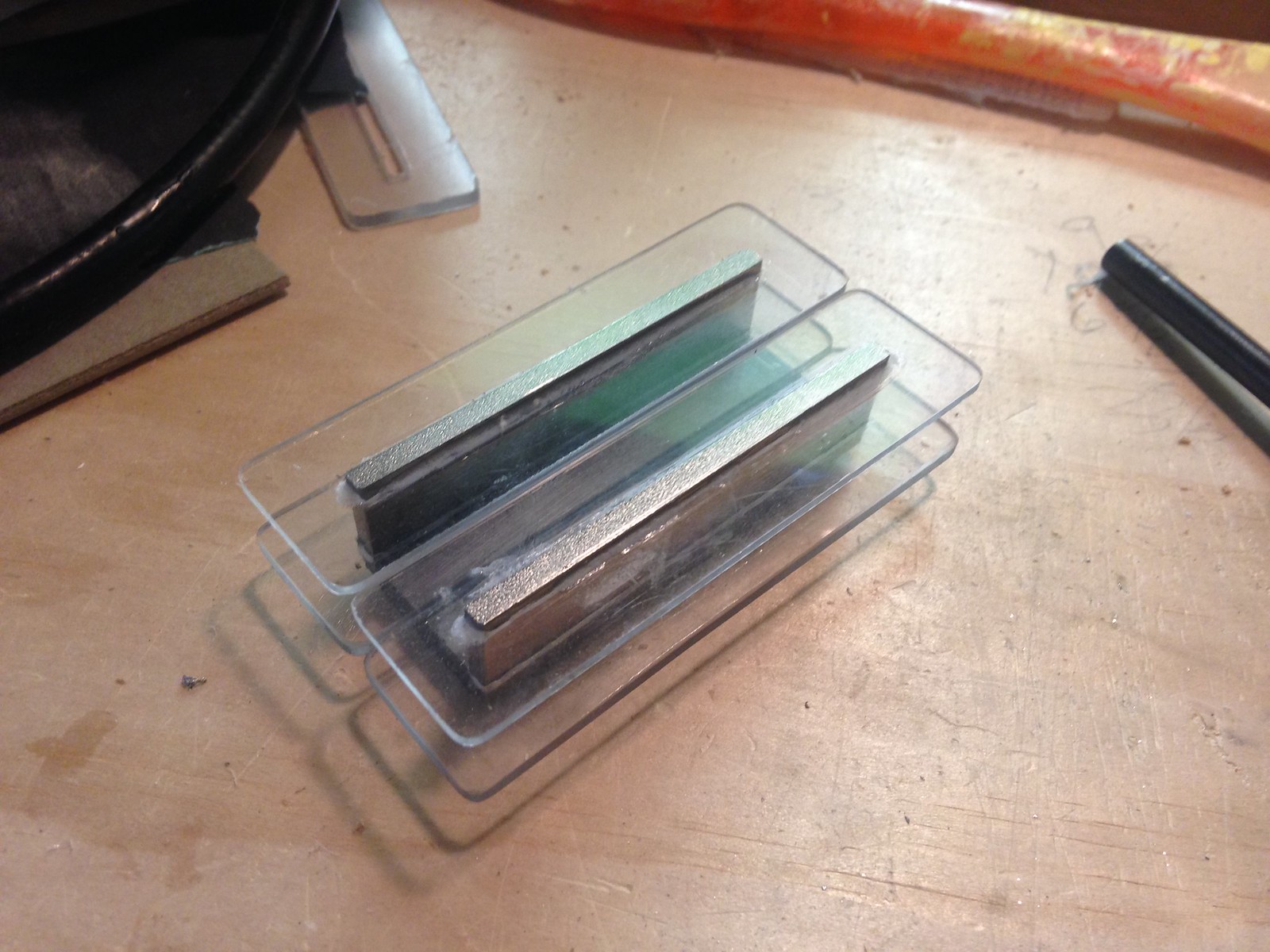

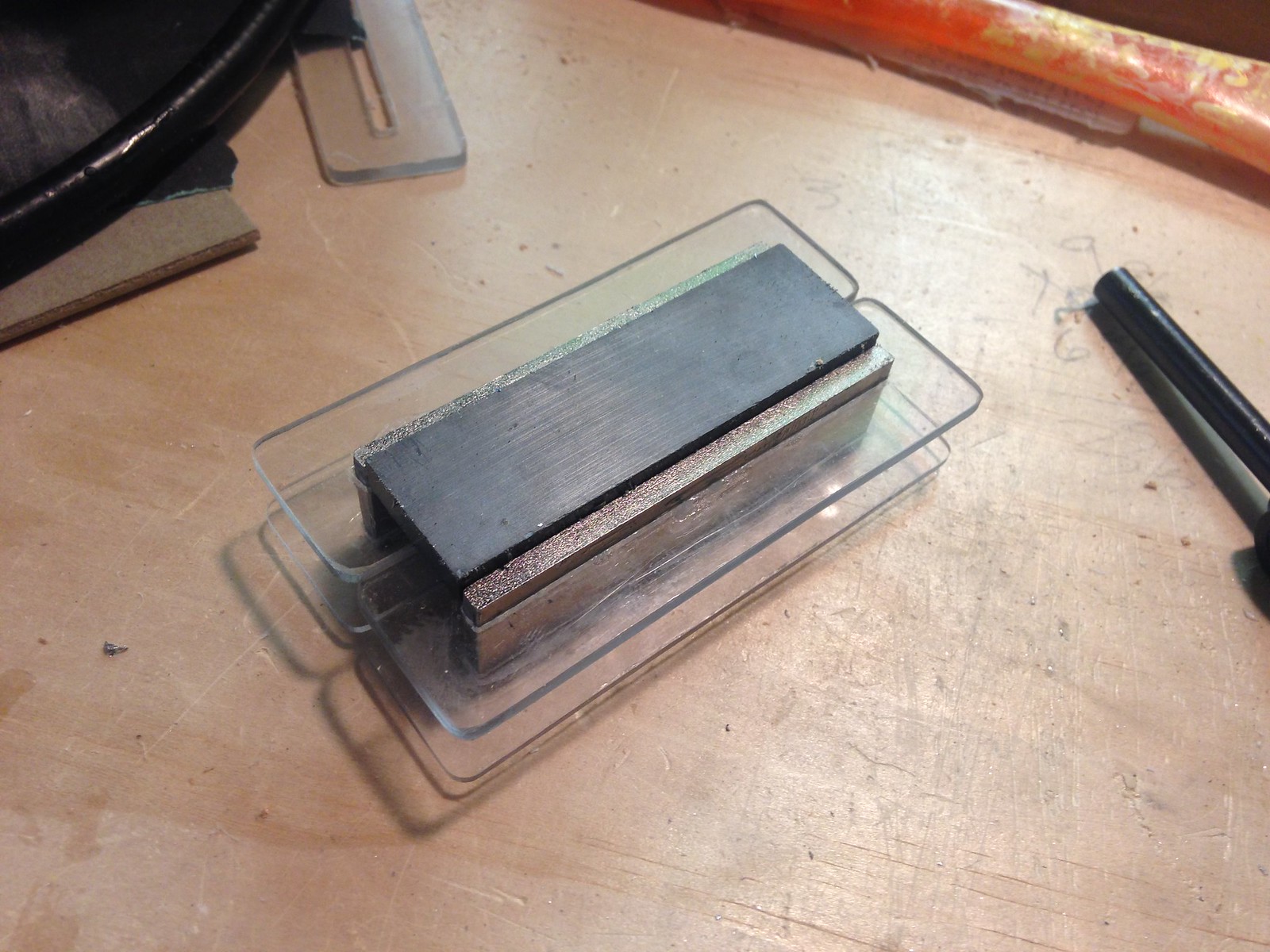

I'm building blade humbucker using steel blades as poles. I'm sort of (emphasis on "sort of") copying an old pickup (T-40) with specs I've gathered on the internet. I was hoping to use a ceramic bar placed underneath placed across both poles with the edges of the magnet in contact with sides of the poles. I can't seem to find a ceramic bar magnet oriented across the width of the bar. Instead, they are all magnetized front and back. I am looking for a bar that is 2.5" L x 0.875" W x 0.125" D oriented in the 0.875" direction. I've spoken to a few vendors, one of which (Adams) was willing to cut them for about $12.00 apiece. Other than that, I've gotten a few quotes with huge minimums.

My questions are:

A) Does the orientation matter, and should I just go for it?

B) Is a ceramic magnet oriented in the 0.875" direction something I should just forget about unless I'm willing to suck it up and buy 50 of them? Does anyone know of a source that stocks such a thing?

C) Is there an alternative material?

Thanks in advance.

Noob here, so any help is appreciated. This is the first time I've posted. I've been lurking around here for a while now.

I'm building blade humbucker using steel blades as poles. I'm sort of (emphasis on "sort of") copying an old pickup (T-40) with specs I've gathered on the internet. I was hoping to use a ceramic bar placed underneath placed across both poles with the edges of the magnet in contact with sides of the poles. I can't seem to find a ceramic bar magnet oriented across the width of the bar. Instead, they are all magnetized front and back. I am looking for a bar that is 2.5" L x 0.875" W x 0.125" D oriented in the 0.875" direction. I've spoken to a few vendors, one of which (Adams) was willing to cut them for about $12.00 apiece. Other than that, I've gotten a few quotes with huge minimums.

My questions are:

A) Does the orientation matter, and should I just go for it?

B) Is a ceramic magnet oriented in the 0.875" direction something I should just forget about unless I'm willing to suck it up and buy 50 of them? Does anyone know of a source that stocks such a thing?

C) Is there an alternative material?

Thanks in advance.

Comment