I have a vintage C12Q Jensen speaker that used to work just fine.

Now I made some tests using three different Jensen speakers, including this one, in an amp of mine.

All of a sudden the C12Q developed a very clear, definite rattle while playing low- and medium- frequency notes with the guitar. It is definitely a ratller, not a buzz or other kind of noise.

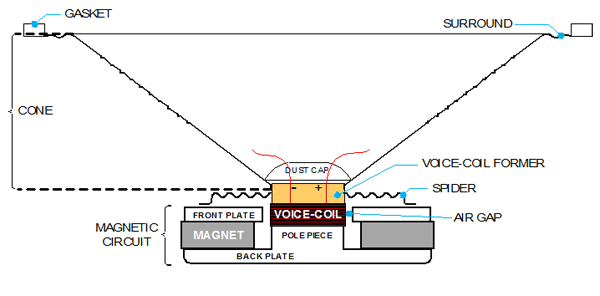

I am almost sure that some small debris (maybe a small tin solder remain) fell inside the speaker somewhere. Actually if I rotate and move the cone around a little bit I can hear the noise of some tiny part rolling somewhere inside the cone.

I have tried to inspect the gap between the basket and the back of the paper cone but I couldn't find anything.

I am very upset because a perfectly working speaker is now unusable due to this silly yet serious problem.

Do you guys have any tip or advice to solve this issue?

EDIT: is there a non-destructive way to disassemble a speaker, or at least to open the dust cap?

Now I made some tests using three different Jensen speakers, including this one, in an amp of mine.

All of a sudden the C12Q developed a very clear, definite rattle while playing low- and medium- frequency notes with the guitar. It is definitely a ratller, not a buzz or other kind of noise.

I am almost sure that some small debris (maybe a small tin solder remain) fell inside the speaker somewhere. Actually if I rotate and move the cone around a little bit I can hear the noise of some tiny part rolling somewhere inside the cone.

I have tried to inspect the gap between the basket and the back of the paper cone but I couldn't find anything.

I am very upset because a perfectly working speaker is now unusable due to this silly yet serious problem.

Do you guys have any tip or advice to solve this issue?

EDIT: is there a non-destructive way to disassemble a speaker, or at least to open the dust cap?

.webm/330px-seek%3D103-Plan_9_from_Outer_Space_(1959).webm.jpg)

Comment