Now with more snarl and 400% more aggression!

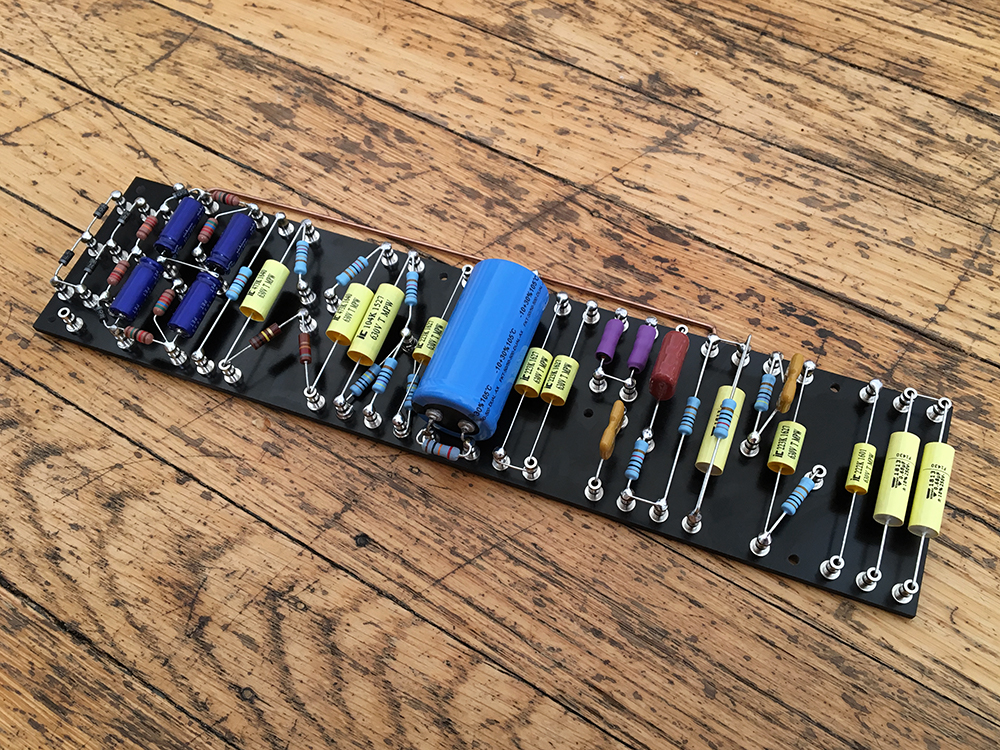

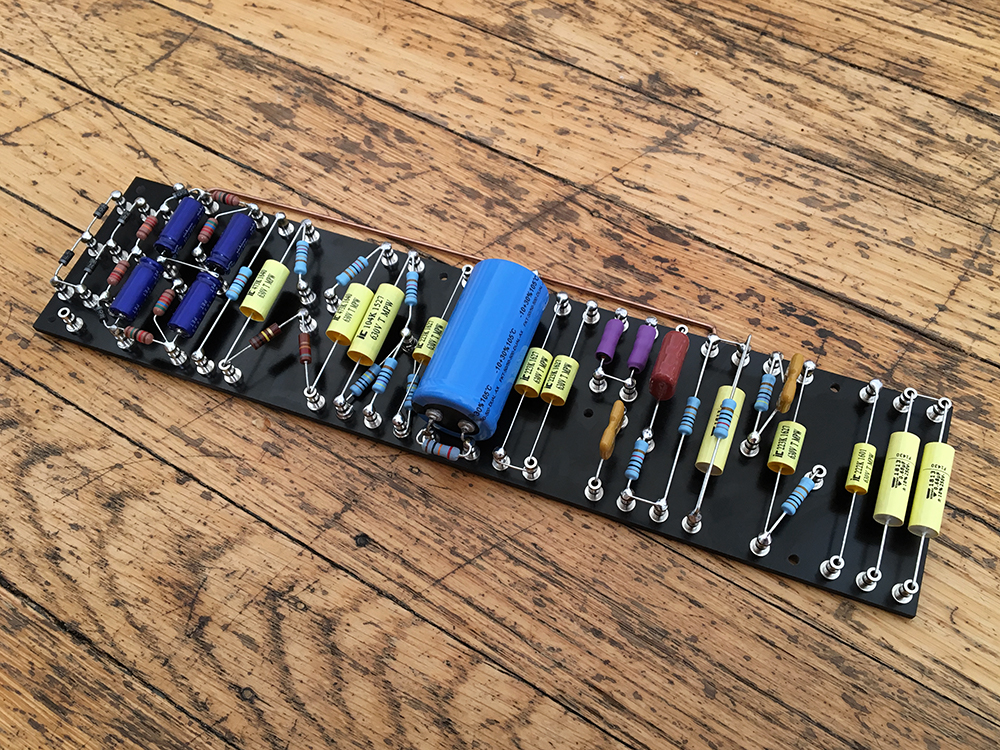

One contains 12v diodes and the other 20v. Different builders who do this same Jose/Cali circuit use different types of clippers. Some use diodes, some zeners, some use other various things. They all do the same basic function.

One contains 12v diodes and the other 20v. Different builders who do this same Jose/Cali circuit use different types of clippers. Some use diodes, some zeners, some use other various things. They all do the same basic function.

Comment