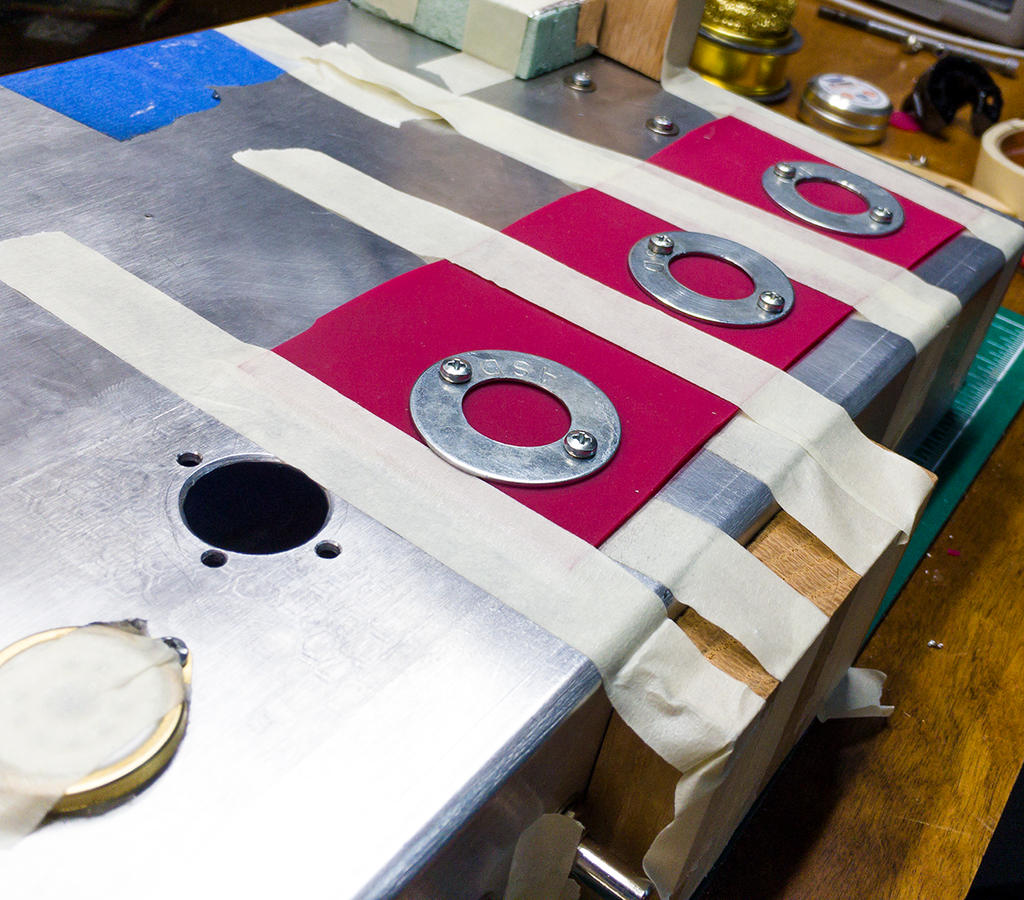

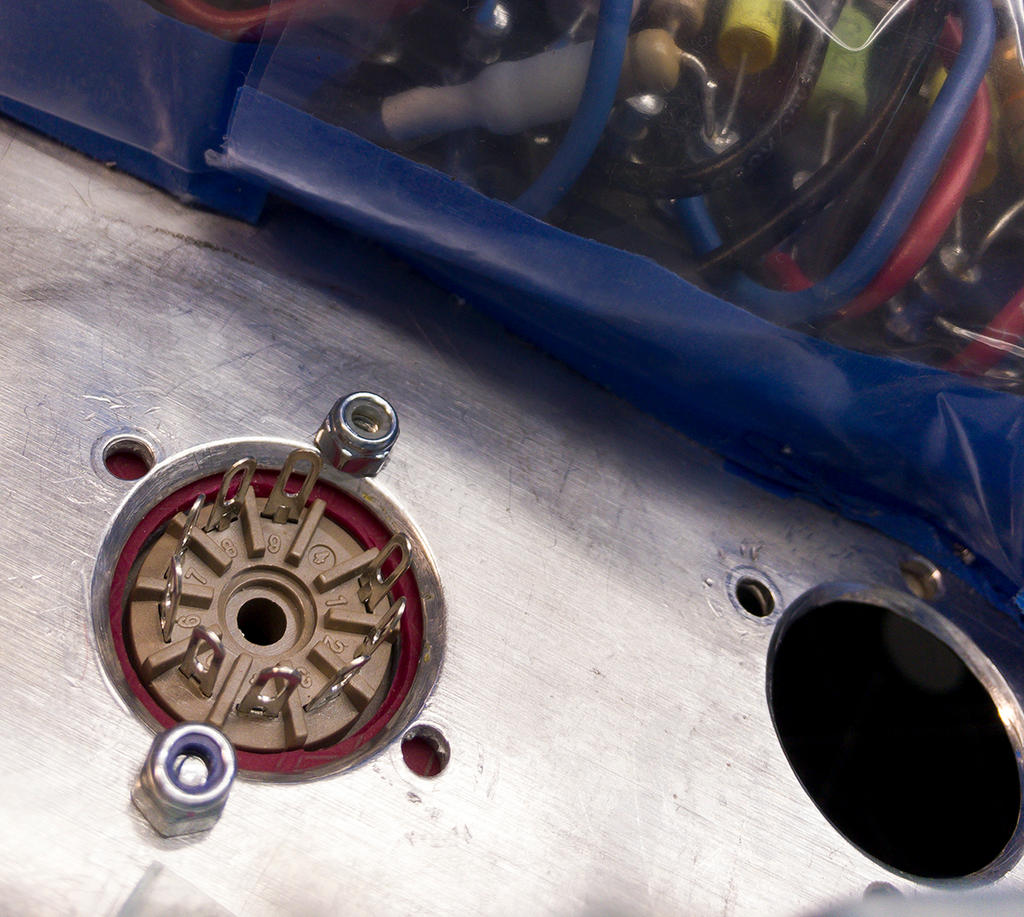

I had been putting off replacing the tube sockets in my amp, because the sockets I'm retrofitting my amp with use a smaller diameter mounting hole and would have looked like garbage leaving the hole the way it is. There is no good way to try and shrink existing holes already drilled in a chassis and make it look great. covering them over always looks lazy to me. Anyway, I decided to use the opportunity to experiment with an Idea I had to try and dampen chassis and tube microphonics. Ultimately, the quickest way for me to move forward with the idea involved drilling out flat washers to the hole diameter I needed for my belton 9-pins. The thought (and actual work) of drilling out flat washers accurately, and drilling into my amplifier with everything still mounted blows so bad that I put it off for over two months. I'm not going go into how i set up drilling the flat washers and masking out my entire amp, unless someone wants to know, because it's a thankless d*ck punch of a job to do right and make it look good. But, I did want to share how I created dampening rings to take advantage of isolating the tube sockets from the chassis. At first I was trying to come up with some way to use RTV, but it would have been extremely difficult to control trying to free-hand something right from the tube. So, then I began thinking about possibly creating some sort of mold, but It would have been time consuming, and robably costly. Then it hit me... I can use a silicone baking sheet as a base material. It met all the criteria I needed for this experiment. This is how I'm going about it:

Thant's the progress as of tonight, and I'll use an xacto to trim the silicone flush with each ring and remove the rest.

Thant's the progress as of tonight, and I'll use an xacto to trim the silicone flush with each ring and remove the rest.

I like that kind of attention to detail in a fabrication project. Did you cut those larger holes in the chassis yourself?

I like that kind of attention to detail in a fabrication project. Did you cut those larger holes in the chassis yourself?

The proper device for the suggested task is a shoulder washer. It's what they're designed for. Grommets could be used but they're designed for a different purpose. Of course they could be made to work and I wouldn't doubt that a lot of people would misuse them to get the job done. But that's what separates designers and fabricators from fixers. Engineer types choose the best part for the task and later on technicians laugh at them and substitute something handy that will do the job.

The proper device for the suggested task is a shoulder washer. It's what they're designed for. Grommets could be used but they're designed for a different purpose. Of course they could be made to work and I wouldn't doubt that a lot of people would misuse them to get the job done. But that's what separates designers and fabricators from fixers. Engineer types choose the best part for the task and later on technicians laugh at them and substitute something handy that will do the job.

Comment