Marvino here, thanks for the message and photos! The 5E3 cab really looks nice, I like the amber wood tone with the black grill cloth contrast. I neglected to mention we use a Leigh jig for router cutting dovetails or straight fingers. The neat thing about this jig is you can adjust the size of the joint as well as the spacing of the joints and run both sides together. Look at leighjig.com. Cheers to all!

Ad Widget

Collapse

Announcement

Collapse

No announcement yet.

Cabinet wood

Collapse

X

-

Yeah, the jig makes all the difference. It imparts a lot of respect for the folks doing it in the old days with a saw...

I have the basic Keller dovetail jig (http://www.kellerdovetail.com/ ); but before now I've done all right with just the plastic finger templates screwwed onto a 2x4 which then was clamped to the workpiece....

Comment

-

How did you cut the rouded corners where the amp goes?Originally posted by pbreyfogle View PostI just finished my first amp last month and I made the cab out of doug fir, which is a tonewood of sorts: A conifer, but stffer and brighter than spruce or cedar. Sounds great and is beautiful.

Also, nice quarter sawn fir is readily available as it is often used for trim in houses.

I put on a coat of amber shellac and then about three brushed on coats of Varythane. I didn't even bother sanding that but buffed it out.

See some pics @

http://instruments.breyfogle.org/Gallery/amps.html

Comment

-

I would imagine with a Jig-Saw, that is how I usually do those kinds of cuts. If you have no jigsaw you can drill a hole in those corners and saw to it.Originally posted by turbolx5oh View PostHow did you cut the rouded corners where the amp goes?DIY Links

Tolex Tutorial

http://www.guitarkitbuilder.com/cont...lifier-cabinet

Chassis:

http://www.guitarkitbuilder.com/cont...lifier-chassis

Turret board:

http://www.guitarkitbuilder.com/cont...d-construction

Comment

-

As far as the wood discussion is concerned, I like to use pine in small Combo cabinets if I am going to Tolex the cabinet.

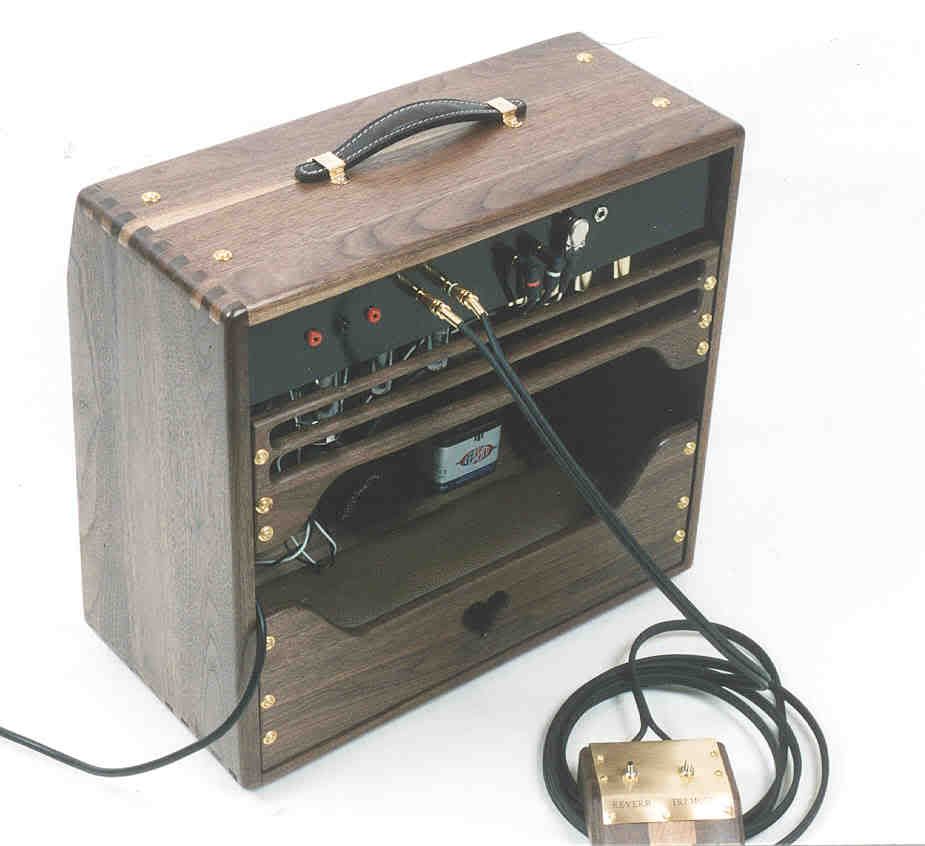

As far as a natural wood look, Poplar is good for a colored stain and is pretty cheap. Wood that is too hard doesn't resonate well, like Oak or Cherry. I have had good luck with Black Walnut, I did a 5F6A varient with walnut and a smaller combo cab. The wood seems to sound pretty good to me, in the smaller cabinet it is probably a little bit "brighter" than the pine but still resonates reasonably well and sounds good to my ears.

DIY Links

DIY Links

Tolex Tutorial

http://www.guitarkitbuilder.com/cont...lifier-cabinet

Chassis:

http://www.guitarkitbuilder.com/cont...lifier-chassis

Turret board:

http://www.guitarkitbuilder.com/cont...d-construction

Comment

-

hi dave, your wood work has come a long way. i drill holes first then cut with a router or jig saw. a better way is to make a template using that methode and if your happy with the quality you can clamp it to the amp and use a router with a flush trim bit to slean up the cut. first make a rough cut with a jig saw so the router is only taking about 1/8 inch off. use a router bit that has the bearing on it that follows the edge of your template.

Comment

-

I downloaded Google SketchUp yesterday, and in a couple hours I had a 3D model of the cabinet for the amp I'm building. It'll look something like this:

Meanwhile, I've been learning how to make dovetail joints:

This POS dovetail jig I got from Sears was designed to make 1/2" half blind joints with 1/2 long pins & tails. I've "hacked" it by cheating, I move the template all the way out and make one cut, then all the way in and make a second cut, which means maneuvering the spinning bit between the pins I've already cut, unsupported by the template (sorta like playing Operation), but I wound up with 1" long pins & tails. I'm playing around with the idea of using a 3/4" deep 1/2" bit to see if I can make some sort of through joint...

I'm planning to use western red cedar, and finishing it with Qualasole. I need to go crawl through the lumber yards in the big city to try and find six board feet of quarter sawn 1x12, and I'll probably have to order the Qualasole online...

Comment

-

Thanks, I'll check it out.Originally posted by lexluthier72 View PostJustin,

If you have not worked with Qualasole as a finish before, It does NOT build up fast...It was developed as a touch up finish. You may get frustrated before you complete the finish using this product. I would recommend Behlen Brushing lacquer.

Comment

-

Originally posted by pbreyfogle View PostDoug fir is kind of like pine and a fair bit harder. Anybody ever used it? Too glassy maybe?

Detuned 1x12 with recycled qtr saw fir, biscuit joint, dado, screw and glue...sounds kind of woody, organic, acoustic, open and projects; plenty of open ariy low end without boomy or boxiness, good mid without being overly punchy and clear top. It was an experiment and happy with the results.

Comment

-

thats a cool cab wrathfuldeity

i didnt want to start a new thread, but i just finished the basics for a open backed 2x10 cab. i accicentally made the thing a bit thinner than i originally planned (meaured the width needed for the baffle and then used that width for the whole cab). this meant that i couldnt mount the baffle along the longer side. i ended up using a baffle made from 19mm pine and mounted it from the 2 ends, which are aprox 280mm wide, and there is nothing supporting the pine baffle for 600+ mm until the other side. my thoughts that using pine would be fine as this way the grain runs in a direction that supports the baffle.

what do you guys think about this? the speakers are rated at 40w (20 each) and im running it with my pp el84 amp that is pretty similar to an ac15.

i made it with the intention of getting a somewhat floating baffle, but is this going over the top? it sounds good but i havent been able to really crank it yet.

it also seems significantly louder than the 4x12 i was using before that with the amp. when i turned it up to roughly the same spot at band the drummer was a bit drowned out and we were playing a bit out of time. the 4x12 cab has 4 plessey 12u50 speakers, which are some australian speakers from the 70's with alnico magnets. nice speakers, but using 15w into it isnt doing them justice imo. plugging in the 200w tube beast that they came with will make me deaf and possible blind and crippled if i do it in the small room i ususally play at home.)

Comment

-

Hardwood cab

I've enjoyed working with Sapelle which is a nice tone wood and works quite well. I usually use figured maple for trim and maybe crotch mahoganey like in this picture.

http://s28.photobucket.com/albums/c2...weedCBScab.jpg

Tubenit

Comment

-

Howdy Folks,

This is a long thread and I'm just getting back on the forum so I hope I'm not repeating someone else's advice that I missed but if you want some great cabinet wood and don't mind glueing up boards - souce about 4" max but I've seen 8" - try pallets and crates from overseas. Sears, for example, gets a lot of stuff made in China and China gets a lot of wood from clear cutting Indonesia so there are lots of "exotic" boards in the Sears wood pile - many stores literally pile the wood beside the dumpster and I'm sure all of them would let you haul off the wood if you asked.

Dendrology never was my strong point but I can still identify some of the genii that I've recycled if not the species and I've found rosewoods - Dahlbergia genus - and some of the pseudo- Mahoganies as well as woods that resemble a pink cherry and some wildly spalted "whatevers" that worked and glued great. Another source is motorcycle/ATV/snow mobile dealers where you get woods that have passed through Japan. While this is no longer the case in the early 1980s Central American mahogany - Switea - was available at your local cycle shop for free (still have quite a bit of this in the atttic).

Build on

Rob

Comment

-

I've recycled wood from pallets as well. Even here in North America you can

find some good hardwood in pallets. A couple of things I don't like about

pallets though is that first the surface of the wood is full of sand and dirt so

you don't want to go putting it through a planer to get a nice surface. I use

a jack plane to scrub off the outer layer. And the nails are held in with some

sort of glue or something and are just about impossible to get out. So you

can't disassemble the create easily without sawing the boards into pieces.

Paul P

Comment

Comment