Felt like sharing, here goes.

So I kept having the typical overheat problem that unsolders the rectifier.

Here's how I fixed it:

How I fixed my DSL 401 overheating problem:

First I located the problem. The stupid little rectifier that heats up and un-solders itself. You'll know you have this problem if when you flip the amp upside down it starts to work again.

Next I drilled a hole directly through the center of the rectifier.

I had a heatsink from an 800 MHz Athlon computer chip laying around. So after about five minutes with a file and a hack saw I had made myself a custom heatsink for the rectifier.

I applied a generous amount of ArticSilver heatsink compound.

And then installed the heatsink with a small machine screw and nut.

I used to insulator on the bottom to protect the PCB.

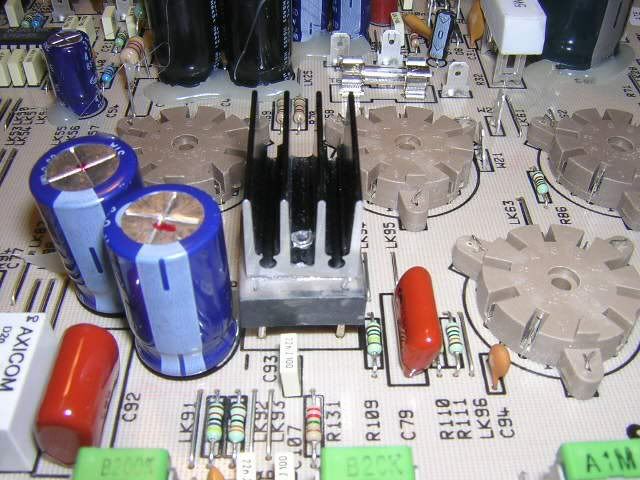

Here's the finished heatsink installed:

Next I tied into the power switch with some 14 gauge wire to power two 110 V fans. I wired the fans to come on as soon as the main power switch is turned on.

Continued Below.....

So I kept having the typical overheat problem that unsolders the rectifier.

Here's how I fixed it:

How I fixed my DSL 401 overheating problem:

First I located the problem. The stupid little rectifier that heats up and un-solders itself. You'll know you have this problem if when you flip the amp upside down it starts to work again.

Next I drilled a hole directly through the center of the rectifier.

I had a heatsink from an 800 MHz Athlon computer chip laying around. So after about five minutes with a file and a hack saw I had made myself a custom heatsink for the rectifier.

I applied a generous amount of ArticSilver heatsink compound.

And then installed the heatsink with a small machine screw and nut.

I used to insulator on the bottom to protect the PCB.

Here's the finished heatsink installed:

Next I tied into the power switch with some 14 gauge wire to power two 110 V fans. I wired the fans to come on as soon as the main power switch is turned on.

Continued Below.....

Comment