The only two amps I know of that use the plastic side panels were the Bassman 135 and the Bassman 70.

The panels are hard to come by. I repaired a few using small pieces of black plastic and Gorilla Glue with sanding/filing.

Another slow, labor intensive task. You could use 1/4 inch plywood and just make covers that screw on, similar to the plastic panels.

The Bassman 135 will throw some heat from the power tubes when cranked up.

The 135 head box was shorter in height than the Bassman 50/100; I think that is why they added the side vents for cooling.

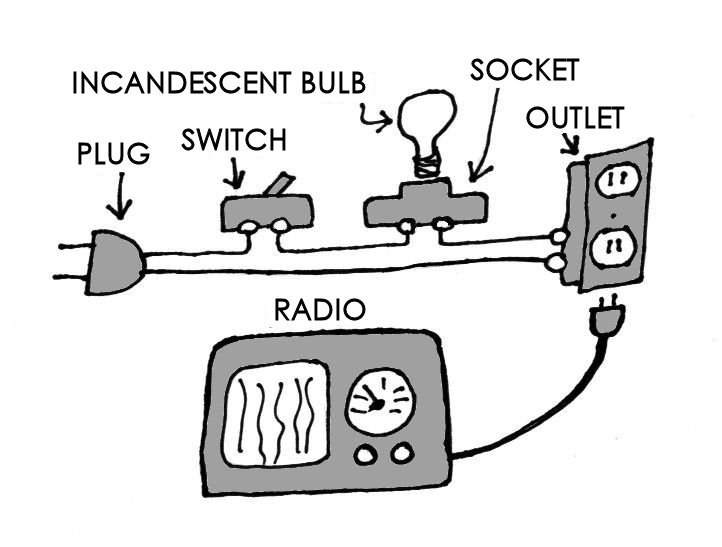

I suppose that if you make the panels, you could add a small fan to the panel that plugs into the outlet on the back on the amp.

The panels are hard to come by. I repaired a few using small pieces of black plastic and Gorilla Glue with sanding/filing.

Another slow, labor intensive task. You could use 1/4 inch plywood and just make covers that screw on, similar to the plastic panels.

The Bassman 135 will throw some heat from the power tubes when cranked up.

The 135 head box was shorter in height than the Bassman 50/100; I think that is why they added the side vents for cooling.

I suppose that if you make the panels, you could add a small fan to the panel that plugs into the outlet on the back on the amp.

Comment