Originally posted by J M Fahey

View Post

Also defining (matching) Vgs(ID) - transfer function of MOSFET - with a single point is like trying to define a line with a single point.

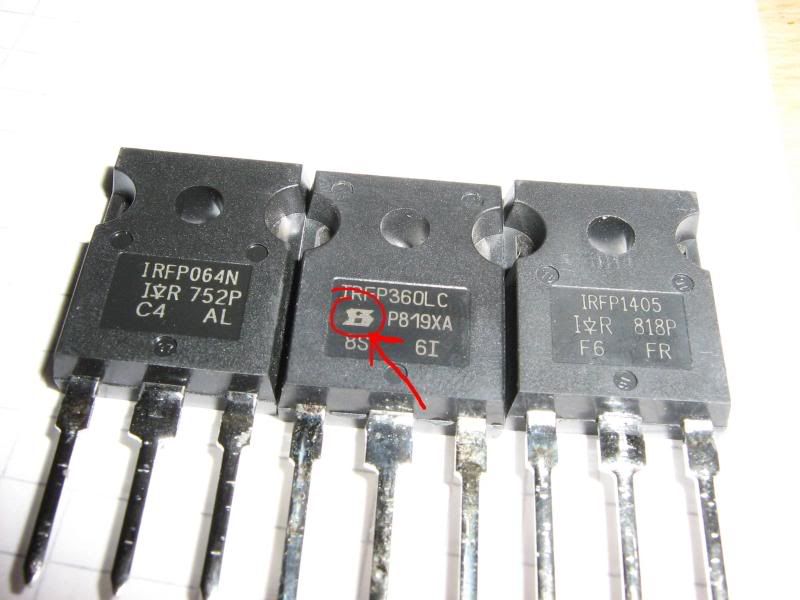

Agree that modern MOSFET with ion implanted gate is very consistent and needs no matching.

Agree that modern MOSFET with ion implanted gate is very consistent and needs no matching.

, I always learn about 25 or 30 y.o. amps going strong and steady

, I always learn about 25 or 30 y.o. amps going strong and steady

Comment