How did JMI expect Vox AC15 owners to install V5 tube shield with choke in the way?

To think non tech Musicians messing with amp guts would be ludicrous.

Amp was assembled and tested at the Factory, on a workbench where that would not have been an issue and premp tube failing would have been a non issue, once they were tested at the Factory.

IF one still failed, a very unlikely issue, it would be replaced by a Tech who would discover the failure when brought the amp for repair.

That they probably had a ton of "short" shields would have been an extra nail in the coffin.

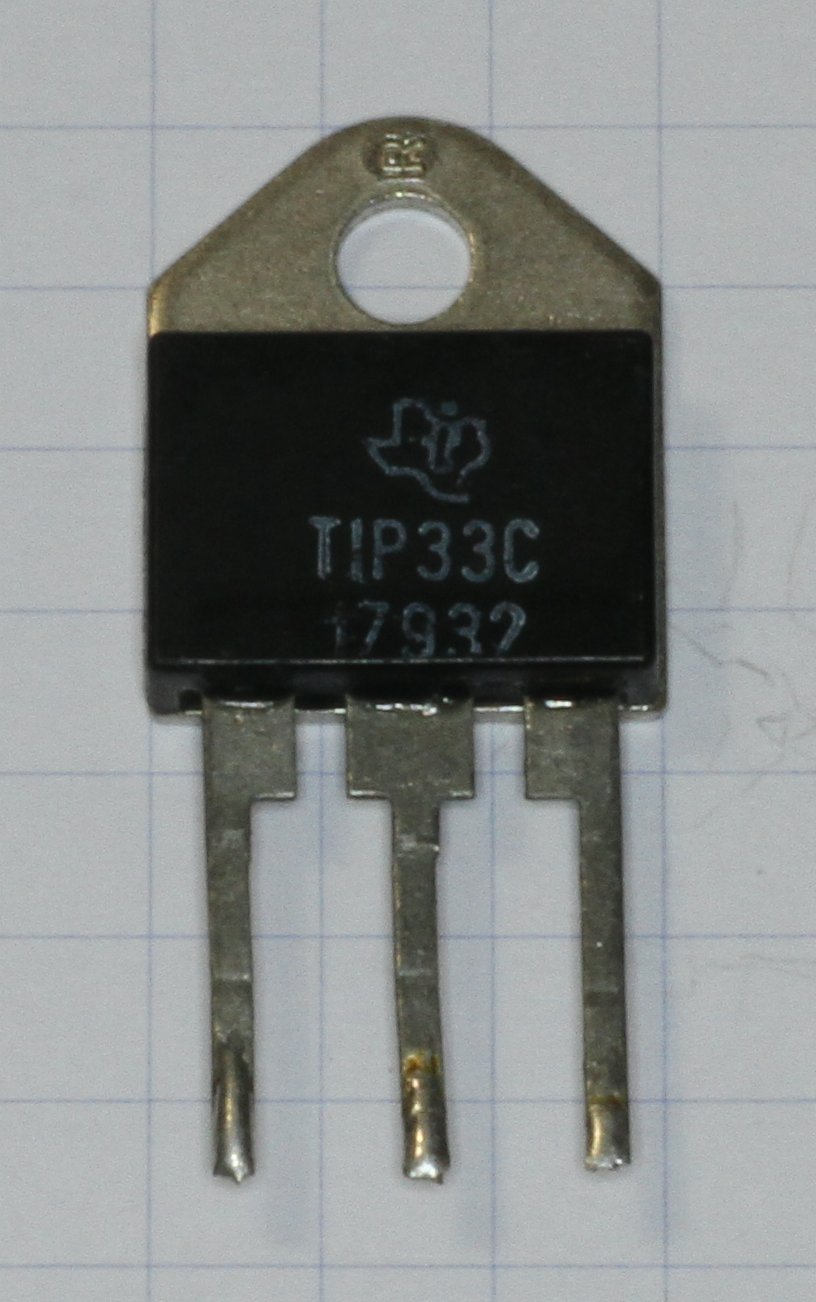

FWIW I still repair *old* Fahey amps from the 80īs, many of which have fried egg shaped TO3 2N3055 or "Plastic TO3" 2N3055, TIP 35 and early TIP142/147 , again with an egg shaped end,

and all modern replacements are plastic rectangular shaped and somewhat larger TO218 or TO247, sometimes they fit very tightly on heat sinks

Itīs not fair complaining about a designer not having a crystal ball and predicting what will be used to maintain their stuff 30 to 60 years later

Comment