Sealed Potentiometers pose a challenge when they get older and begin to show signs of aging. Inevitably, they still can get dirty and noisy, displaying that symptomatic "scratchy" sound when rotating the actuator. *Randall Aiken has an interesting write-up about having used these types of pots, as well as non-sealed types over an 18 year perspective in the Q&A section of his tech pages:

Technical Q&A

In his Q&A, he brings up valid pros and cons about using these kinds of pots. In spite of the cons of using sealed pots, I still like to use them for all the benefits he brings up. Plus, I do like the rugged construction, and the way they look in an amplifier. Hey, I'm a sucker for presentation.

While they obviously aren't as easy to clean as CTS/Alpha style pots, they certainly don't need to be discarded. While a little bit of work and some care, they can be cleaned and restored without damaging them. Here is how I do it:

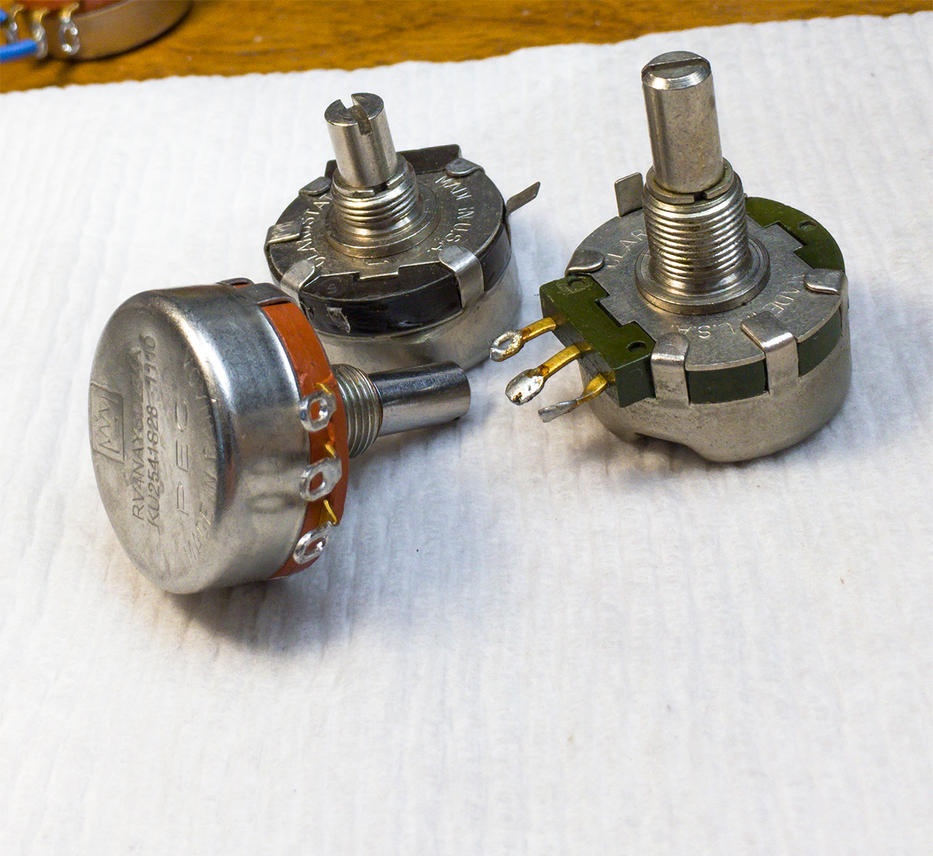

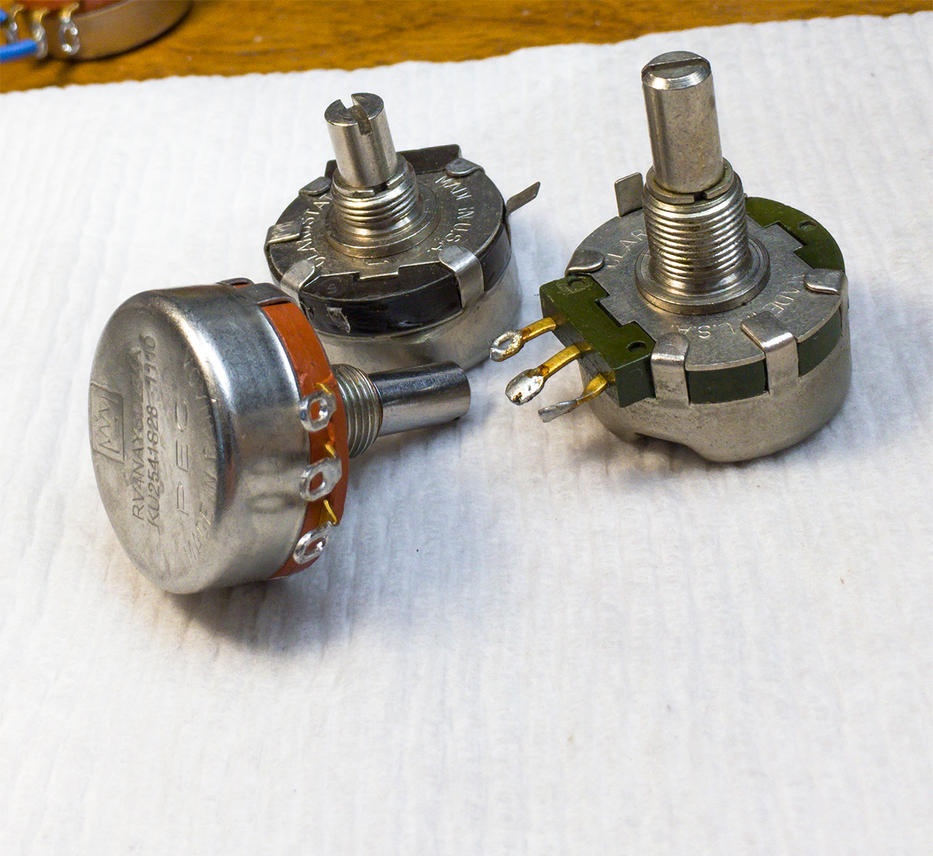

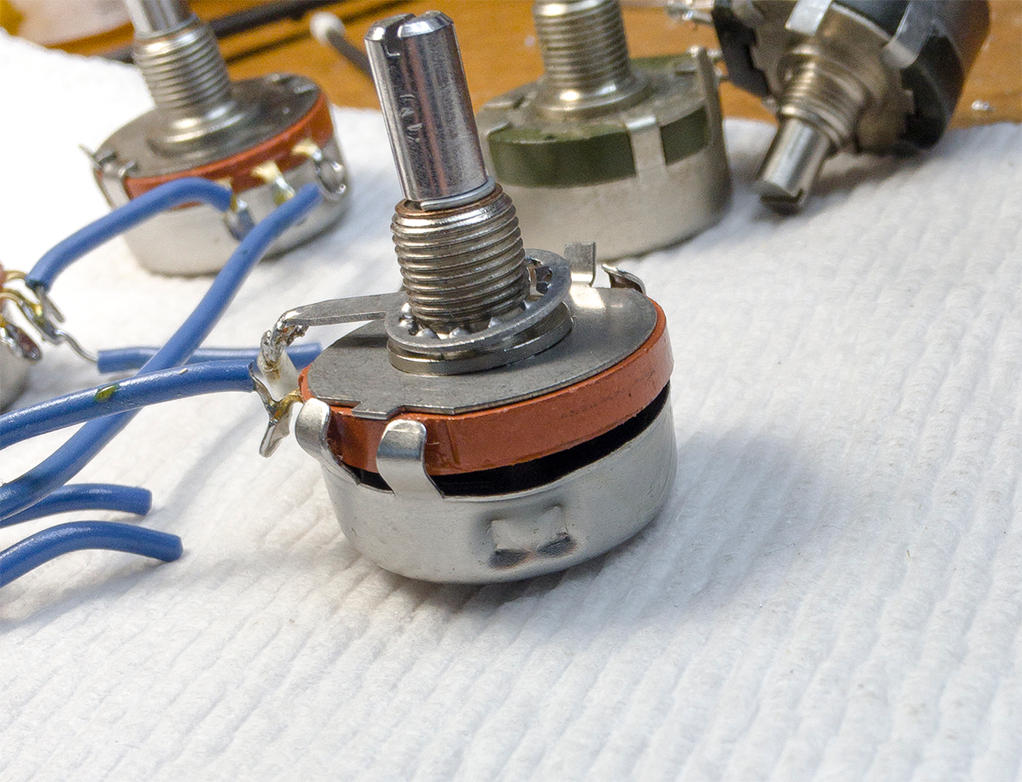

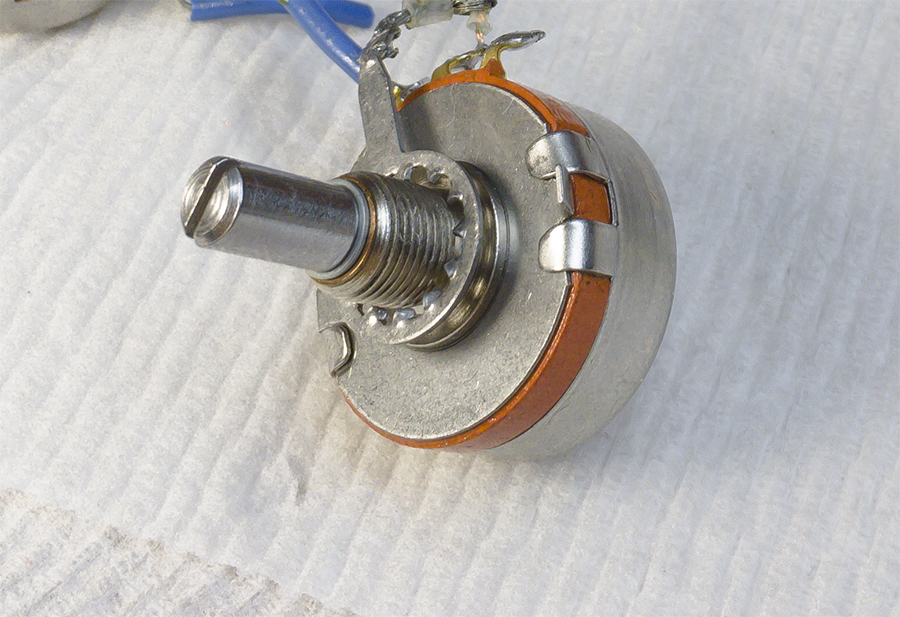

Here are a few examples of RV4/Mil style sealed potentiometers

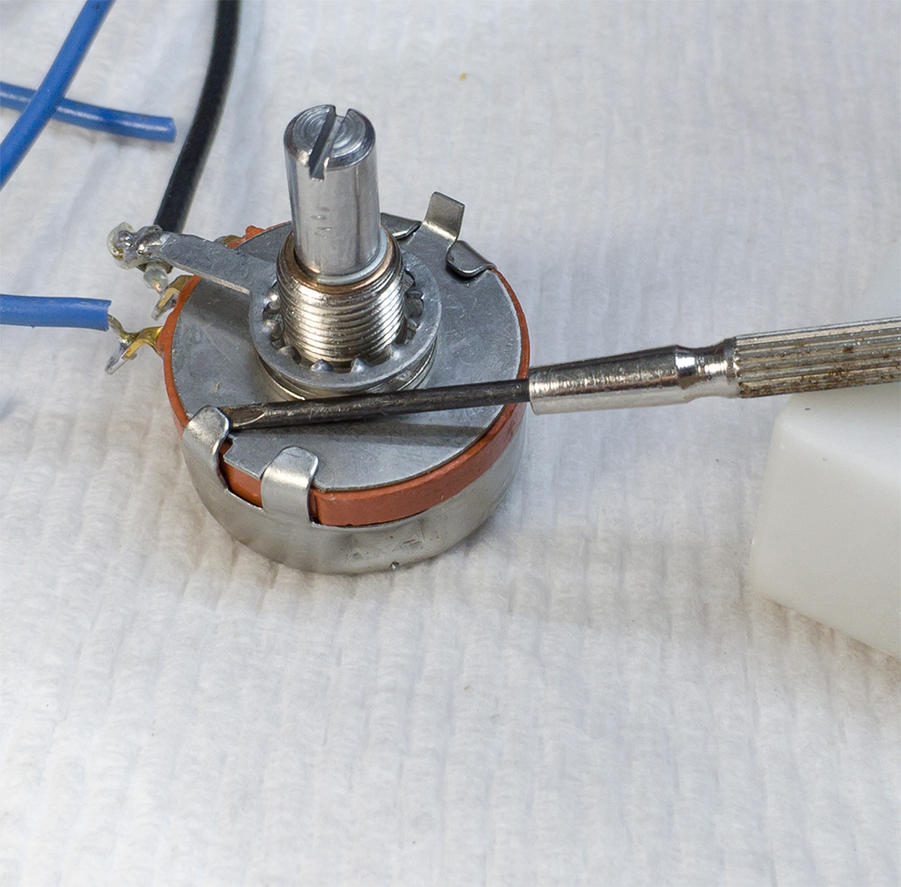

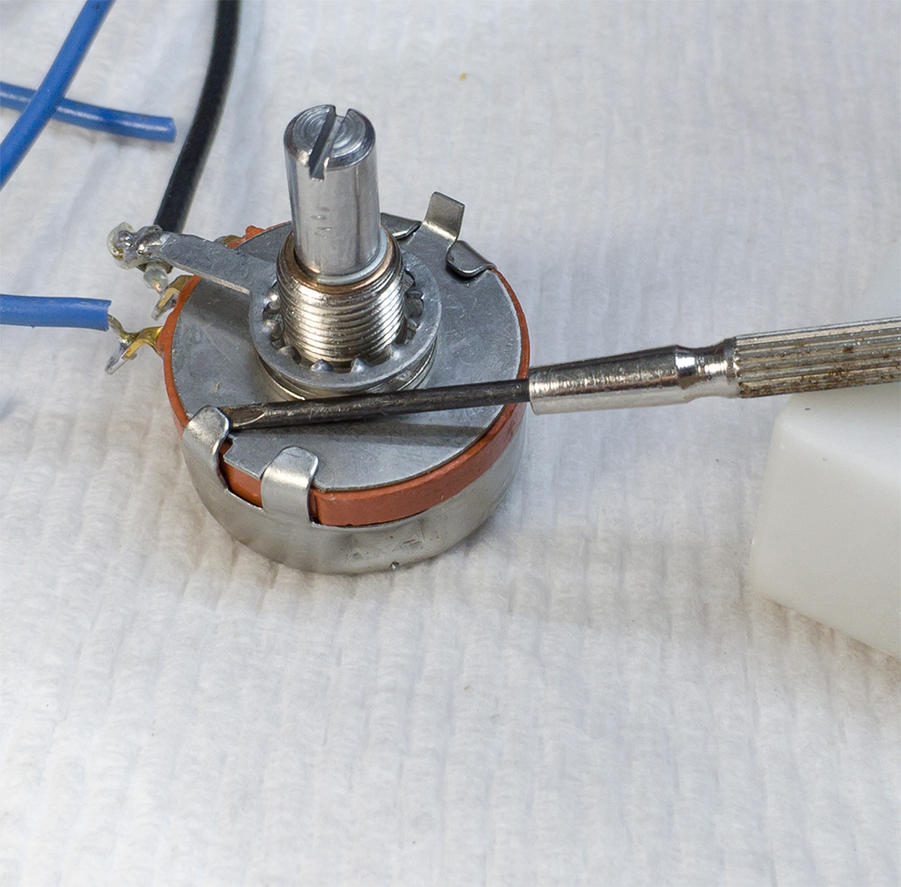

First I take a small tool (in this case, a small eyeglasses repair screwdriver) and gently wedge it under the tabs securing the back of the pot.

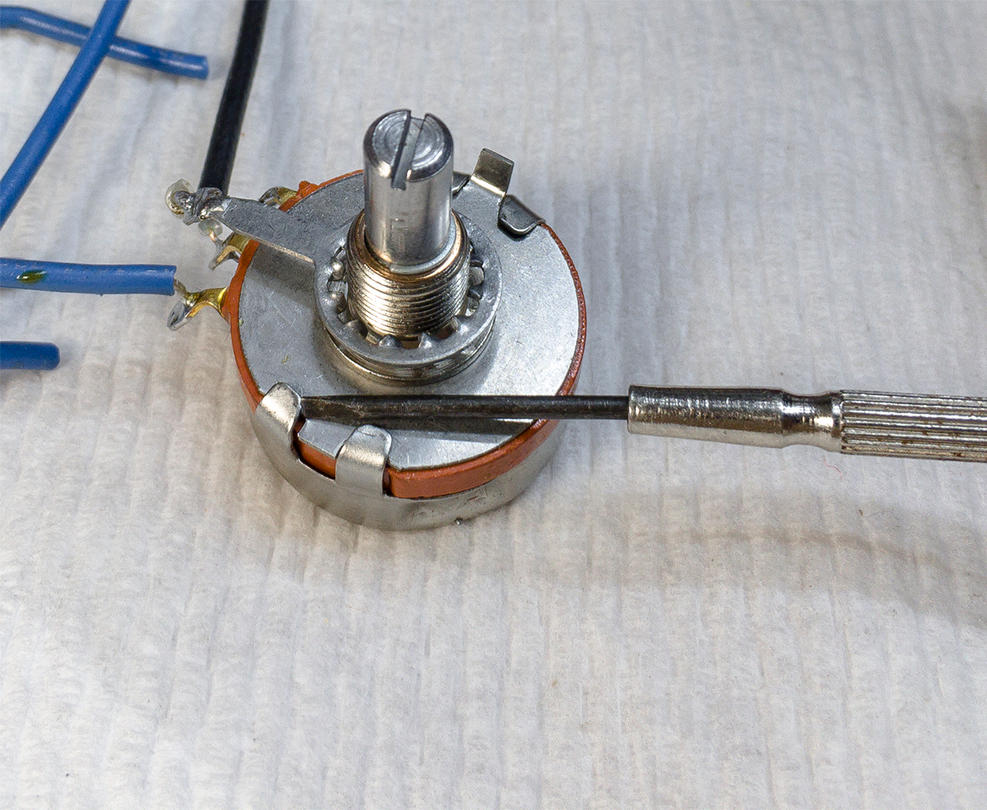

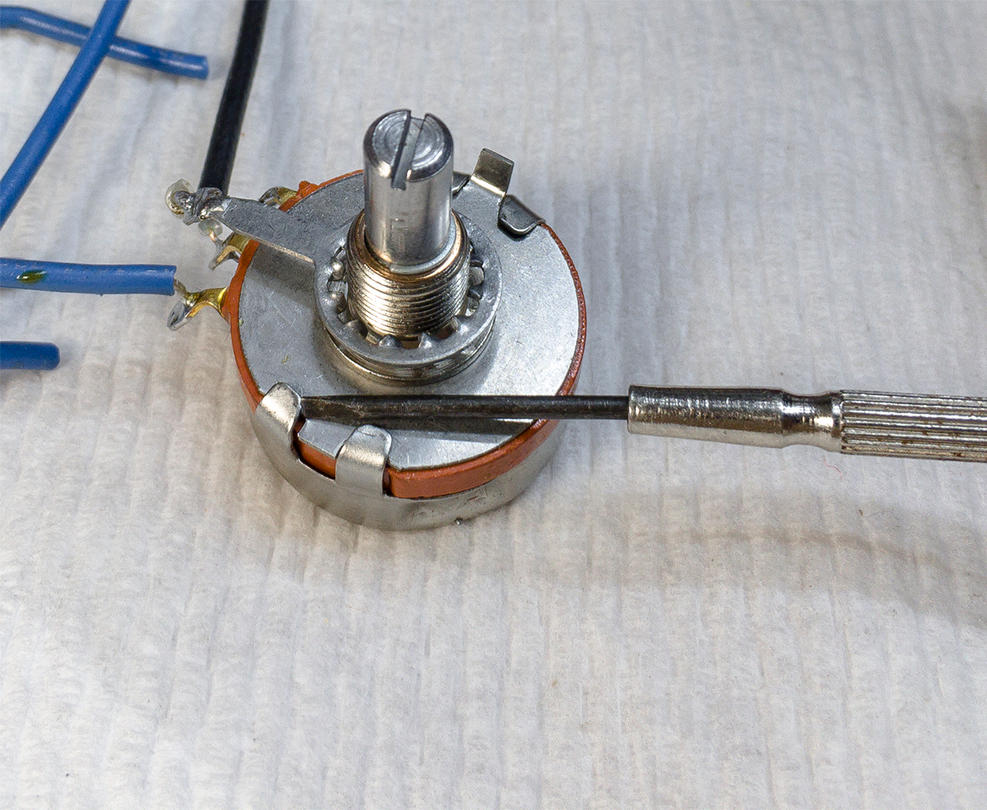

Then, using the same tool (or slightly larger screwdriver), I carefully leverage a little bit of space by slightly pushing the tab up and away from the body. Be cautious not to damage the finish or molding.

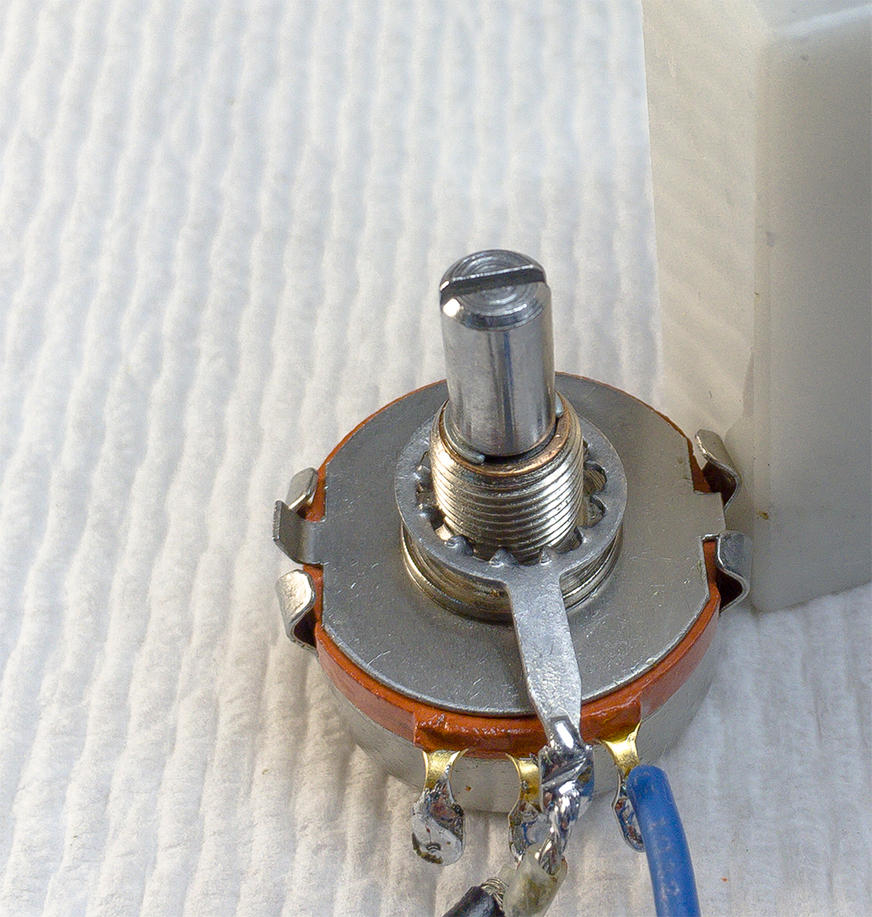

Do not overly bend the tabs, you only need about this much clearance.

continued below...

Technical Q&A

In his Q&A, he brings up valid pros and cons about using these kinds of pots. In spite of the cons of using sealed pots, I still like to use them for all the benefits he brings up. Plus, I do like the rugged construction, and the way they look in an amplifier. Hey, I'm a sucker for presentation.

While they obviously aren't as easy to clean as CTS/Alpha style pots, they certainly don't need to be discarded. While a little bit of work and some care, they can be cleaned and restored without damaging them. Here is how I do it:

Here are a few examples of RV4/Mil style sealed potentiometers

First I take a small tool (in this case, a small eyeglasses repair screwdriver) and gently wedge it under the tabs securing the back of the pot.

Then, using the same tool (or slightly larger screwdriver), I carefully leverage a little bit of space by slightly pushing the tab up and away from the body. Be cautious not to damage the finish or molding.

Do not overly bend the tabs, you only need about this much clearance.

continued below...

Comment