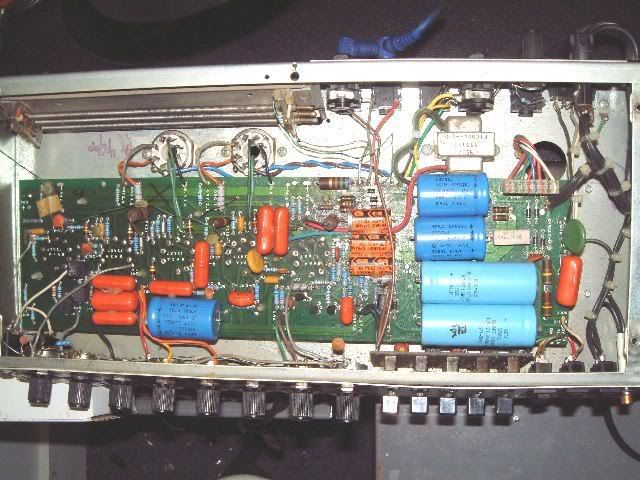

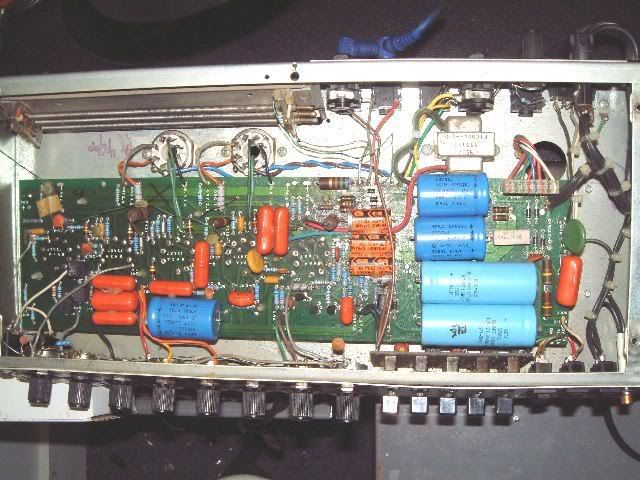

I just installed a new OT on a Mesa .50 Caliber, 1990. My next project is to replace the electrolytics. The components are top mounted yet there seems to be solder on both sides of the board (more on the bottom). I can't get to the bottom without first removing 45 wires. I tried 650 degrees on my iron figuring I could heat up the lead of the cap and just lift it out....no dice. I'm sure there is an obvious solution without removing the board but this is my first board of this type. Previous boards have been so much easier to remove. Can I just snip the leads from the old caps and solder to that, or would that be shoddy work?

thanks as always for the advice.

Gary

thanks as always for the advice.

Gary

Thanks for all the advice.

Thanks for all the advice.

Comment