I was just wondering if the plexi panels from Home depot and lowes would be ok for making circuit boards? Noone local sells G10 and I sometimes need to build a circuit board and dont want to wait til it arrives in the mail. If not plexi then perhaps another material found in local hardware shops.

Ad Widget

Collapse

Announcement

Collapse

No announcement yet.

Plexi Panels-Good for Turrets Boards?

Collapse

X

-

in my hands acrylic /plexiglass is difficult to drill without tear out and/or splitting, so pressing in turrets doesn't go very well, not does soldering them as the base material melts quite low (<150C)

some have made terminal strips work though...

Acrylic/perspex for turret-boards?

-

I always get my turret boards from Mccaster Car. Here is a link to a previous thread about this. I usually buy the 3 inch wide, 1/8 inch thick, 4 foot sections for ~$15, plus a few dollars shipping.

You can find it here ... product number 8557K154.

I have seen others that use plexi panels, but it is not rated for the heat that some wire wound resistors can give off. I also prefer the G-10 garolite because it is less likely to suffer from tweed disease.

Comment

-

After posting earlier I went to McMaster and found that exact board material and they have always delivered my orders pretty quick. I was looking at the lexan stuff and the 1/8 thickness stuff is quite flimsy.

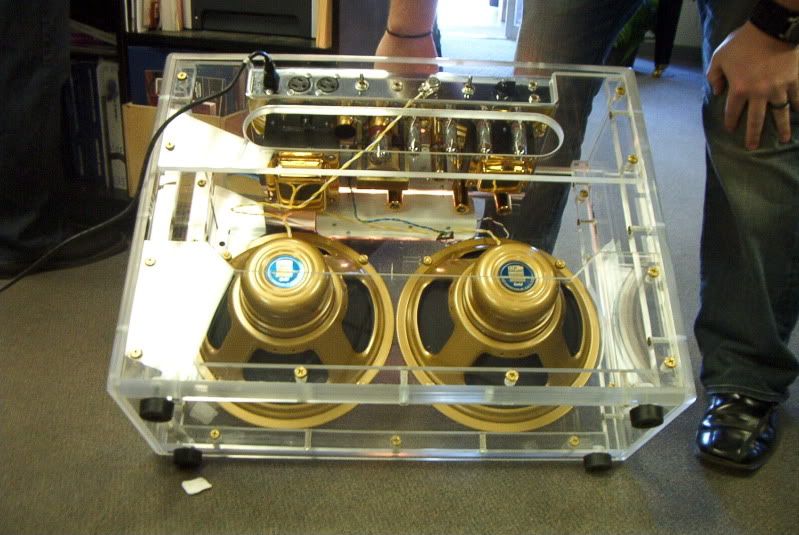

Tedmich, did you build that amp? That is pretty sic!

I guess if I want to build something quickly I could just use terminal strips.

Comment

-

Wow. Awesome. Thanks for sharing, that is really obscenely cool imo. It's almost like it is naked, I think I am getting turned on a little bit..Originally posted by tedmich View Postin my hands acrylic /plexiglass is difficult to drill without tear out and/or splitting, so pressing in turrets doesn't go very well, not does soldering them as the base material melts quite low (<150C)

some have made terminal strips work though...

Acrylic/perspex for turret-boards?

Comment

-

Plexi is not a good idea for turret boards mainly because of heat. When you solder it it will only take a few seconds to melt. In general, it's not so bad to work with, you just need the right drilling speed and a very pointy bit made for plastic so it won't crack. 1+ on G10 from Mcmaster Carr, and it will only take a few days to get to you. But do your sel a favor and cut it with a wet tile saw to avoid the nasty dust. I think Phenolic would be the next best thing to G10.

Comment

-

When I was still in the San Francisco bay area I went to a local shop and bought a 4'x4'x1/16" piece of G10 for $70 US. I'm still building off of it. You can't imagine how many circuit boards a 4'x4' sheet will make. It cuts pretty well with any of the Dremel wheels. VERY worth the investment. When I need a board, I just make it.

Whether you need to order it and pay a little more or buy a big piece from a local distributor, my experience with owning a big piece of circuit board material has been very positive. Sure there's an initial investment. But it's soooo worth it."Take two placebos, works twice as well." Enzo

"Now get off my lawn with your silicooties and boom-chucka speakers and computers masquerading as amplifiers" Justin Thomas

"If you're not interested in opinions and the experience of others, why even start a thread?

You can't just expect consent." Helmholtz

Comment

-

its some guys Fender clone I believe, stylistically its possible to flame polish acrylic edges to be totally clear, and glue with almost no visible seam. Also I'd have to be really anal in my lead routing were I to go this "naked"Originally posted by Austin View PostWow. Awesome. Thanks for sharing, that is really obscenely cool imo. It's almost like it is naked, I think I am getting turned on a little bit..

check this one

also with edges done wrong

I'd love to plug a Dan Armstrong into it...

Comment

-

You don't worry about lexan being flimsy. They are polycarbonate, thick enough, it is bullet resistance. They use this for storm window for hurricane windows. We use this for HV cages that make these amplifiers baby voltages. They are no plexiglass, much much stronger. Try bend and break the 1/8 lexan and you'll see. I paid good money to have double windows ( not double pane) for my house with the inner window 1/4 lexan for security. Those that live in hurricane area should know what I am talking about those security double window.Originally posted by chunkitup View PostAfter posting earlier I went to McMaster and found that exact board material and they have always delivered my orders pretty quick. I was looking at the lexan stuff and the 1/8 thickness stuff is quite flimsy.

Tedmich, did you build that amp? That is pretty sic!

I guess if I want to build something quickly I could just use terminal strips.Last edited by Alan0354; 08-31-2012, 10:41 PM.

Comment

-

Acrylic is beautiful and a great insulator, but the problem is *heat* resistance, rather the mechanical one.

G10 is great, but I fear its dust and it anyways destroys regular drills and saws, so my time tested solution for the last 43 years has been to buy big 4' by 4' Pertinax (phenolic) boards.

I make short production runs, so hand cutting with a Dremel wheel is not cost/time effective for me.

Pertinax can be slightly heated to make it softer and less brittle and cut with foot operated shears.

I can cut 20 boards in 5 minutes or less if I want to.

It can also be easily drilled with regular drills and I still have my 42 Y.O. eyelet applicator.

Boards end up being *very* similar to what classic Marshalls used before going PCB.

Only once made a board with the black waxed fiberboard used by Fender and dropped it out in disgust. Gosh !!!

Pertinax is easy to find in industrial electrical supply shops, because it's an established insulating and mounting material for custom jobs.Juan Manuel Fahey

Comment

-

too bad CF twill looks so good

but has problems with electrical conductivity

http://wings.buffalo.edu/eng/mae/cmr...%20polymer.pdf

Comment

-

Will Formica work? Imagine a woodgrain eyelet board. How about marble or slate?WARNING! Musical Instrument amplifiers contain lethal voltages and can retain them even when unplugged. Refer service to qualified personnel.

REMEMBER: Everybody knows that smokin' ain't allowed in school !

Comment

Comment