Originally posted by novosibir

View Post

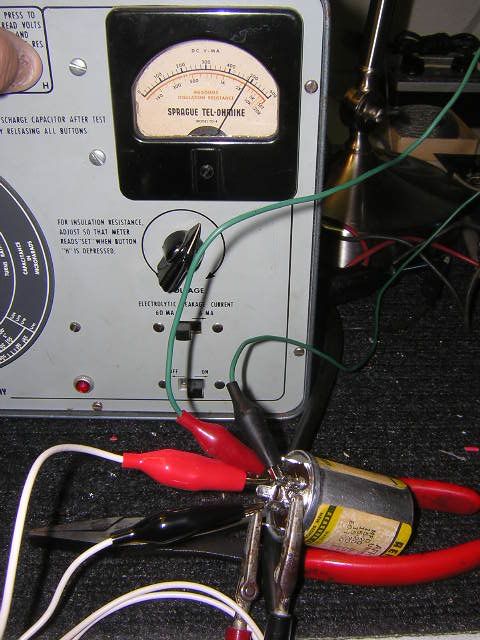

I'll get to put my project in practice and see whether it was worth doing when I finally decide to quit screwing around and put my Princeton Reverb back together. If I've got a new capacitor I might check it for leakage and it it's below the figure for leakage it's formed well enough for me.

He's been so much surprised, that his amp came to life again and got back its 'old sound' like before, just even a bit better and said, that he nearly couldn't stop playing his amp again in the reherasing room, hence his phone call came so late.

He's been so much surprised, that his amp came to life again and got back its 'old sound' like before, just even a bit better and said, that he nearly couldn't stop playing his amp again in the reherasing room, hence his phone call came so late.

Comment