First post.

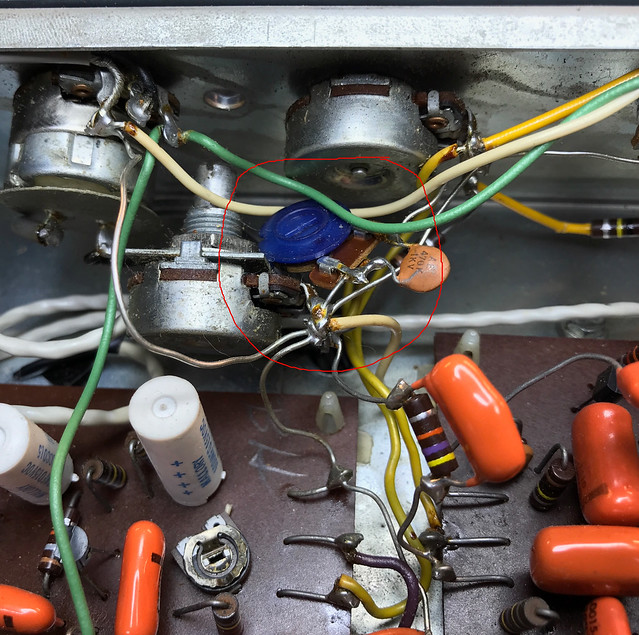

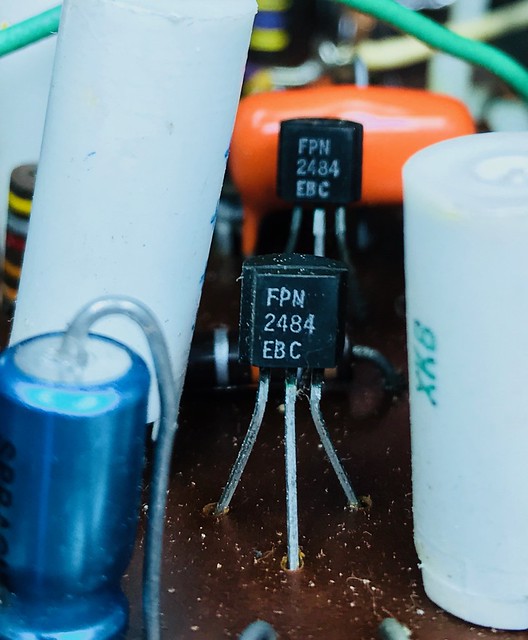

I have an EP-3 that I'm sort of refurbishing. I've had this one about 2 years (i've owned a couple in the past) and I know my way around them mechanically. When it comes to the electronics on them, I'm kind of a noob. I was supposed to be getting a "serviced" unit, and i guess by serviced they meant SOS head wire cut/deactivated, some weird mods thrown in... you get the idea. I overpaid for it in the condition it was in, however it does work and from what i could compare to, works fairly well.

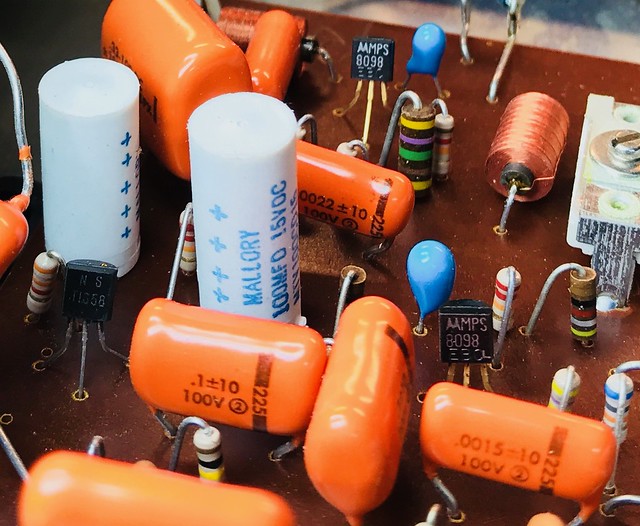

Except I feel like I should be getting way more sustain say, around the midway mark of the sustain pot. It definitely sustains, but i just know i've heard better, longer repeats on other units and i'm sure there is something wrong. Before I go on, i will point out that I have re-loaded the tape cartridge with some 1/4" Scotch recording tape since I just have tons of them laying around, but I can't comment on the integrity of the tape. I adjusted the record level, I messed around a little with the sustain and bias trimmers with no real changes.. also I have already re-capped the power section and plan to do the remaining electrolytics. I de-magged the heads and cleaned them thoroughly.

At this point I'm going to try and get my hands on a friend's EP-3 which i know is in supurb mechanical and electrical condition and try to compare the two and see what's what. But I do remember working on one a while back and getting it to the point where it was working great mechanically but the echoes were fading off real quick. And we had a friend look at it and he changed some components but I can't recall what he changed. I'll have to have a look at the schematic and see what goes where...

if anyone has any specific knowledge of the EP-3 or this particular issue I'd love to hear.

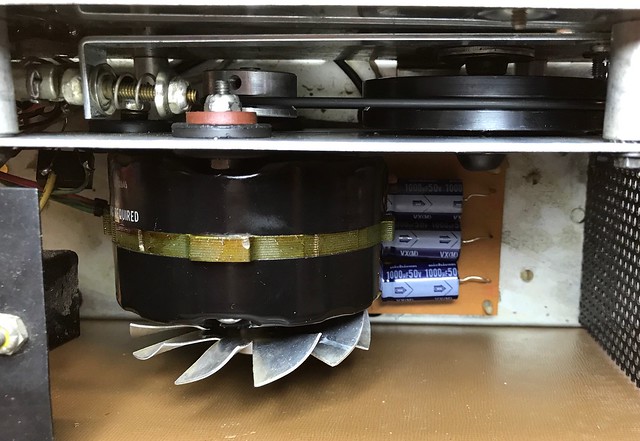

The other problem I have is the wow and flutter which i think is actually the motor. I have the solenoid adjusted for the pinch roller but I still get this little flutter. I'm going to put a new belt on it, but Is taking apart these motors safe to do without risk of destroying them or am i better off leaving it alone and / or finding a new one?

Thanks for any feedback-

I have an EP-3 that I'm sort of refurbishing. I've had this one about 2 years (i've owned a couple in the past) and I know my way around them mechanically. When it comes to the electronics on them, I'm kind of a noob. I was supposed to be getting a "serviced" unit, and i guess by serviced they meant SOS head wire cut/deactivated, some weird mods thrown in... you get the idea. I overpaid for it in the condition it was in, however it does work and from what i could compare to, works fairly well.

Except I feel like I should be getting way more sustain say, around the midway mark of the sustain pot. It definitely sustains, but i just know i've heard better, longer repeats on other units and i'm sure there is something wrong. Before I go on, i will point out that I have re-loaded the tape cartridge with some 1/4" Scotch recording tape since I just have tons of them laying around, but I can't comment on the integrity of the tape. I adjusted the record level, I messed around a little with the sustain and bias trimmers with no real changes.. also I have already re-capped the power section and plan to do the remaining electrolytics. I de-magged the heads and cleaned them thoroughly.

At this point I'm going to try and get my hands on a friend's EP-3 which i know is in supurb mechanical and electrical condition and try to compare the two and see what's what. But I do remember working on one a while back and getting it to the point where it was working great mechanically but the echoes were fading off real quick. And we had a friend look at it and he changed some components but I can't recall what he changed. I'll have to have a look at the schematic and see what goes where...

if anyone has any specific knowledge of the EP-3 or this particular issue I'd love to hear.

The other problem I have is the wow and flutter which i think is actually the motor. I have the solenoid adjusted for the pinch roller but I still get this little flutter. I'm going to put a new belt on it, but Is taking apart these motors safe to do without risk of destroying them or am i better off leaving it alone and / or finding a new one?

Thanks for any feedback-

Comment