I am green insofar as ever having any work experience truing and crowning frets.

the communist want to fab a brand new neck for my raptor plus tk, a mere 35usd freeship.

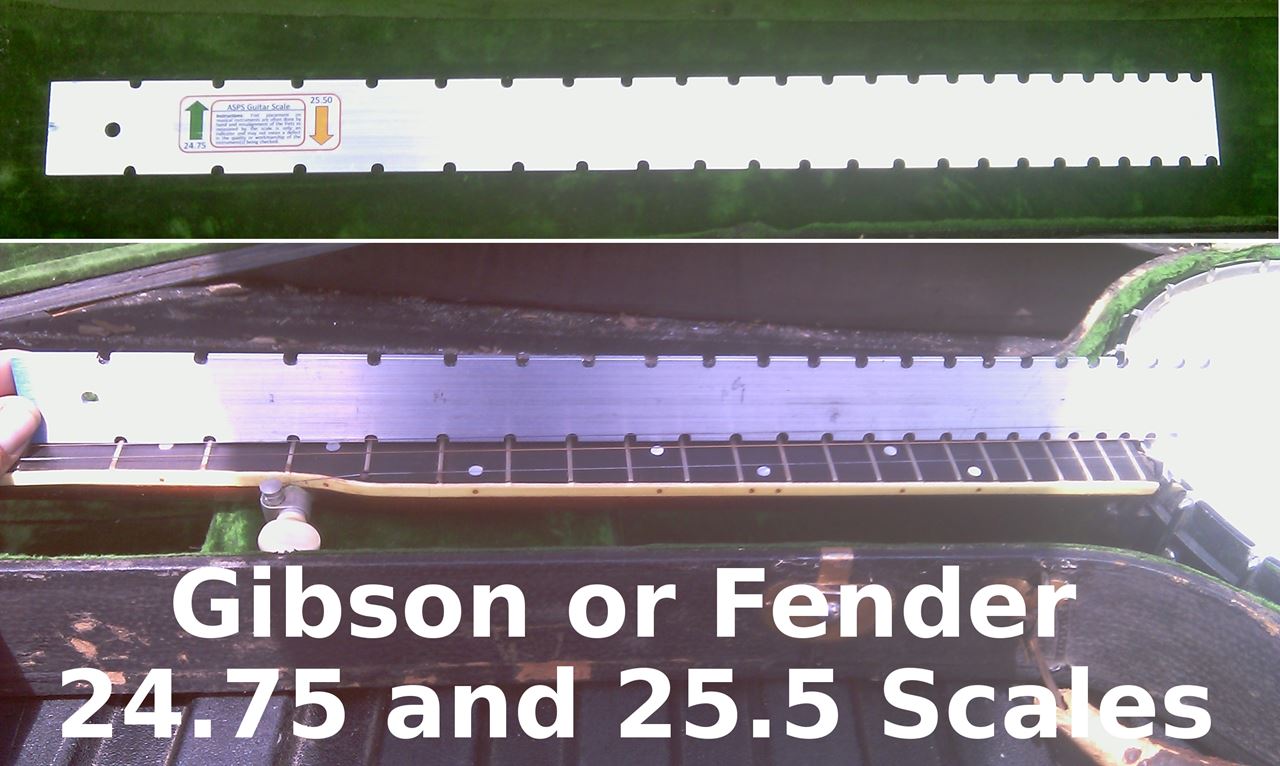

but the 80's neck is magical (why is fingerboard so thick like cigarette diameter?), just that slapping has worn the lower frets, not grooves, but instead very shallow scallops, say less than a tenth of height. so I bought the communist machining bar, communist crowner, communist [.4, .6, 1, 1.5, 2]k silicon carbide wet sand paper, tacky adhesive spray can, communist fretboard ruler un-notched.

but I have not started anything, why, apprehensive, I may screw it up.

here's my worry: I can reconfigure the truss wheel, neck detached from body, to obtain precise neck straightness necessary for leveling.

but when normal pressure, slight as it be, is applied by the leveling bar, the neck will flex some amount.

how much? depends on how much normal force is being applied, and, what is supporting (cradle jig?) this neck during leveling.

see, if the neck deflects while being leveled, this will impart counter-bowing with respect to the frets longitudinal axis, once deflection is vacated.

I went as far as acquiring an ace hardware store's display crescent wrench cardboard box, quite sturdy, narrow, long, shallow.

the boxes endpoints longitudinally speaking were carved (dremel chews cardboard like margarine!) to receive the underside curvature of the neck.

the depth of the carved yokes was to submerge the neck adequately into the coffin such that plaster of paris or dental imprinting rubber could be pooled and solidified creating a bracing jig for a neck already configured straight. the neck must be coated with a release (paraffin naptha) and thermal considerations must be attended (exothermic, endothermic), by staging laminates.

the web videos make it seem so elementary, as if 2 or 3 thousands of an inch untrue leveling is acceptable. I don't know this realm, or margin of tolerant error. but it would appear I should at least accomplish the leveling trueness to that of my tooling precision, otherwise why even purchase such precise tooling? I was also concerned of the adhesive tacky spray. does it increase error? typical layer thickness would be well over the 2 or 3 thousandths of an inch, and it is compressible, and I don't know if upon compression does it stay compressed or does it recover back to 2 or 3 thousandths thickness?

do I knock out the nut to allow leveler to reciprocate easier longitudinally? the leveler is the long one.

what grit do I start off with? 320? 400? 600? 1200? 1500? 2000? do I use a lube? which lube is harmless? or do I impregnate the fingerboard rosewood with tung, let cure two weeks, then test whether pure water can be used as the lubricant over the tung treated fingerboard? you do not want to disturb the bite tight compression inset by factory fret installation, it is very very important insofar as sounding as an endpoint.

I look at this operation from this perspective: the amount of metal removal is so mininscule, one could easily remove too much, and that's disaster. so what's the surest safest way? remove metal in a prescribed fashion that permits the least amount of metal removal to accomplish truing. the web shows folks black marsh penning frets and then leveling observing when the black deposit gets erased by machining. don't you think the highs will erase first? that'll expose the scalloped recessions black. but how do you control furtherance of machining (recessions still black) without any black guidance remaining on the highs? when the leveler is being reciprocated longitudinally, its lateral girth will (accommodate) abrade the non-black highs as well as the telltale blacks of recessions. I do not know how else to explain this but for some reason this appears as blind machining.

your recommendations and advisories are welcomed. thank you in advance.

the communist want to fab a brand new neck for my raptor plus tk, a mere 35usd freeship.

but the 80's neck is magical (why is fingerboard so thick like cigarette diameter?), just that slapping has worn the lower frets, not grooves, but instead very shallow scallops, say less than a tenth of height. so I bought the communist machining bar, communist crowner, communist [.4, .6, 1, 1.5, 2]k silicon carbide wet sand paper, tacky adhesive spray can, communist fretboard ruler un-notched.

but I have not started anything, why, apprehensive, I may screw it up.

here's my worry: I can reconfigure the truss wheel, neck detached from body, to obtain precise neck straightness necessary for leveling.

but when normal pressure, slight as it be, is applied by the leveling bar, the neck will flex some amount.

how much? depends on how much normal force is being applied, and, what is supporting (cradle jig?) this neck during leveling.

see, if the neck deflects while being leveled, this will impart counter-bowing with respect to the frets longitudinal axis, once deflection is vacated.

I went as far as acquiring an ace hardware store's display crescent wrench cardboard box, quite sturdy, narrow, long, shallow.

the boxes endpoints longitudinally speaking were carved (dremel chews cardboard like margarine!) to receive the underside curvature of the neck.

the depth of the carved yokes was to submerge the neck adequately into the coffin such that plaster of paris or dental imprinting rubber could be pooled and solidified creating a bracing jig for a neck already configured straight. the neck must be coated with a release (paraffin naptha) and thermal considerations must be attended (exothermic, endothermic), by staging laminates.

the web videos make it seem so elementary, as if 2 or 3 thousands of an inch untrue leveling is acceptable. I don't know this realm, or margin of tolerant error. but it would appear I should at least accomplish the leveling trueness to that of my tooling precision, otherwise why even purchase such precise tooling? I was also concerned of the adhesive tacky spray. does it increase error? typical layer thickness would be well over the 2 or 3 thousandths of an inch, and it is compressible, and I don't know if upon compression does it stay compressed or does it recover back to 2 or 3 thousandths thickness?

do I knock out the nut to allow leveler to reciprocate easier longitudinally? the leveler is the long one.

what grit do I start off with? 320? 400? 600? 1200? 1500? 2000? do I use a lube? which lube is harmless? or do I impregnate the fingerboard rosewood with tung, let cure two weeks, then test whether pure water can be used as the lubricant over the tung treated fingerboard? you do not want to disturb the bite tight compression inset by factory fret installation, it is very very important insofar as sounding as an endpoint.

I look at this operation from this perspective: the amount of metal removal is so mininscule, one could easily remove too much, and that's disaster. so what's the surest safest way? remove metal in a prescribed fashion that permits the least amount of metal removal to accomplish truing. the web shows folks black marsh penning frets and then leveling observing when the black deposit gets erased by machining. don't you think the highs will erase first? that'll expose the scalloped recessions black. but how do you control furtherance of machining (recessions still black) without any black guidance remaining on the highs? when the leveler is being reciprocated longitudinally, its lateral girth will (accommodate) abrade the non-black highs as well as the telltale blacks of recessions. I do not know how else to explain this but for some reason this appears as blind machining.

your recommendations and advisories are welcomed. thank you in advance.

Comment