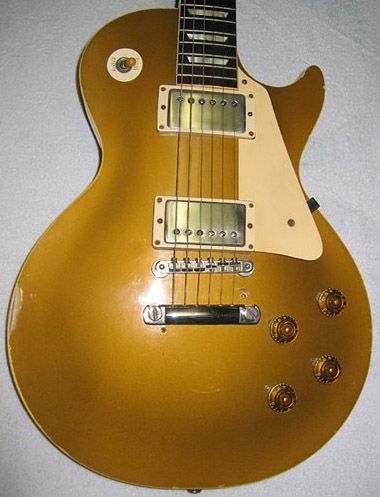

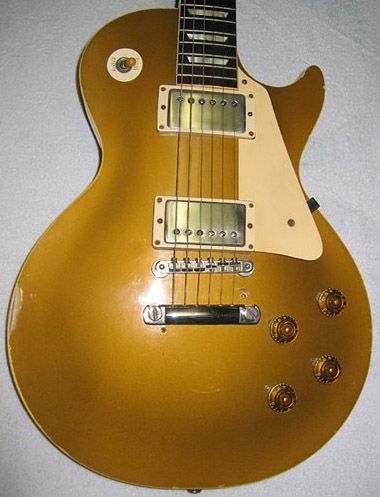

Here is a picture of a 57' Les Paul that has no sticker PAF's and it is claimed to have stainless covers. These covers don't seem to have any tarnish but the hardware has very tarnish also. Clearly these have either brushed or buffed surface. I would think that considering the age that these would have tarnished some if they were nickel. I have never had a PAF with this kind of cover in hand but clearly Gibson used brushed and not plated covers for a short time. The close up photo has a color buffed raw cover on the left buffed the way Gibson did it in the 50's.

Comment