So I promised I searched (even with the added power of Google) but I couldn't find an answer to this. I just wound the Jaguar-style pickups for a guitar I'm building (still a way's off but I had nothing else to do tonight). This is my first time doing single coils and using vulcanized fiber. I was pretty happy with things until I pulled the pickup off and really got a look at it! Turns out the windings have warped the top (thinner) forbon!? It's worse at the edge by the outer-most magnets, which I'd expect. But I'm more concerned about:

1- Why did this happen?

2- How can I avoid it in the future?

3- Can this be fixed or is it a rewind?

4- Should I be concerned that it's pushed it so much that at the edges tape is no longer covering my magnets inside?

5- If this is a must rewind should I expect to be able to reuse this bobbin, or is it toasted?

Specs in case they're needed: Mojotone Jaguar kit with 8560 winds of 42AWG SPN.

Also, I should mention that the forbin fit tightly on the magnets (had to ream a bit, but they finally hammered in) and they were superglued with thin CA.

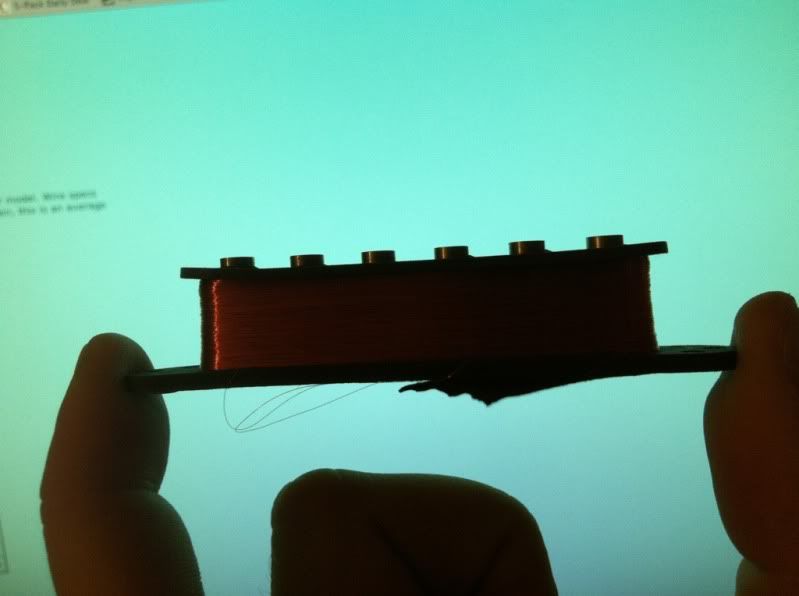

Here it is in silhouette. As you can see one side pushes up more than the other. Taking both sides into account though, there is a 1/32" dip at the center of the bobbin.

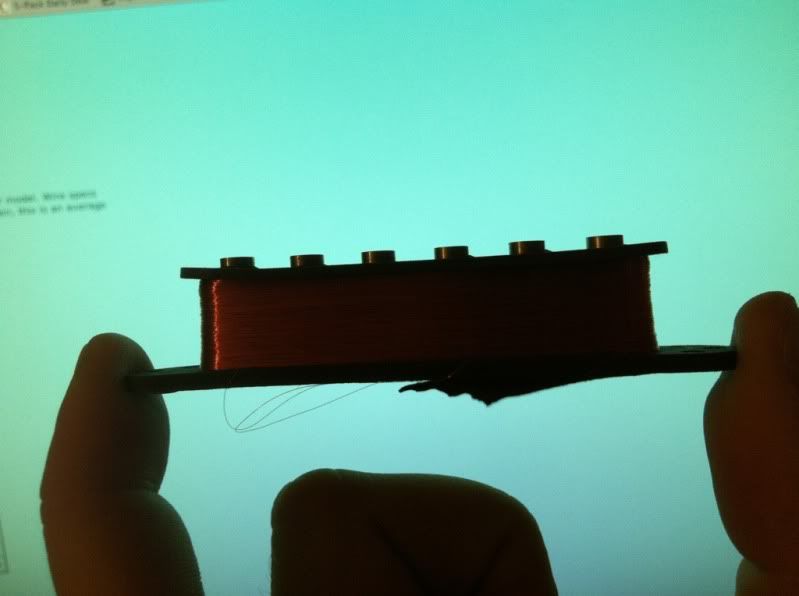

Here it is with the straight edge of the other bobbin placed against it to give a nice reference to just how curved it became. Once again, 1/32" at the center.

Thanks in advance,

Chris

1- Why did this happen?

2- How can I avoid it in the future?

3- Can this be fixed or is it a rewind?

4- Should I be concerned that it's pushed it so much that at the edges tape is no longer covering my magnets inside?

5- If this is a must rewind should I expect to be able to reuse this bobbin, or is it toasted?

Specs in case they're needed: Mojotone Jaguar kit with 8560 winds of 42AWG SPN.

Also, I should mention that the forbin fit tightly on the magnets (had to ream a bit, but they finally hammered in) and they were superglued with thin CA.

Here it is in silhouette. As you can see one side pushes up more than the other. Taking both sides into account though, there is a 1/32" dip at the center of the bobbin.

Here it is with the straight edge of the other bobbin placed against it to give a nice reference to just how curved it became. Once again, 1/32" at the center.

Thanks in advance,

Chris

I've been trying to clear my backlog instead of work new projects. But with the cold in the shop, sometimes it's nicer to just come in and wind.

I've been trying to clear my backlog instead of work new projects. But with the cold in the shop, sometimes it's nicer to just come in and wind.

Comment