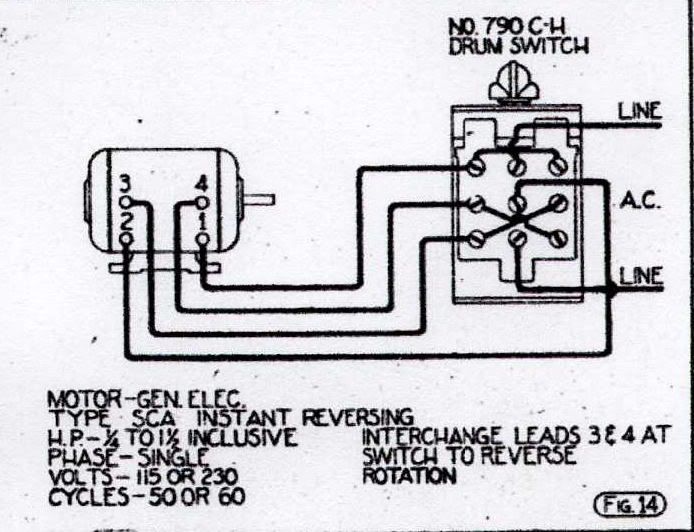

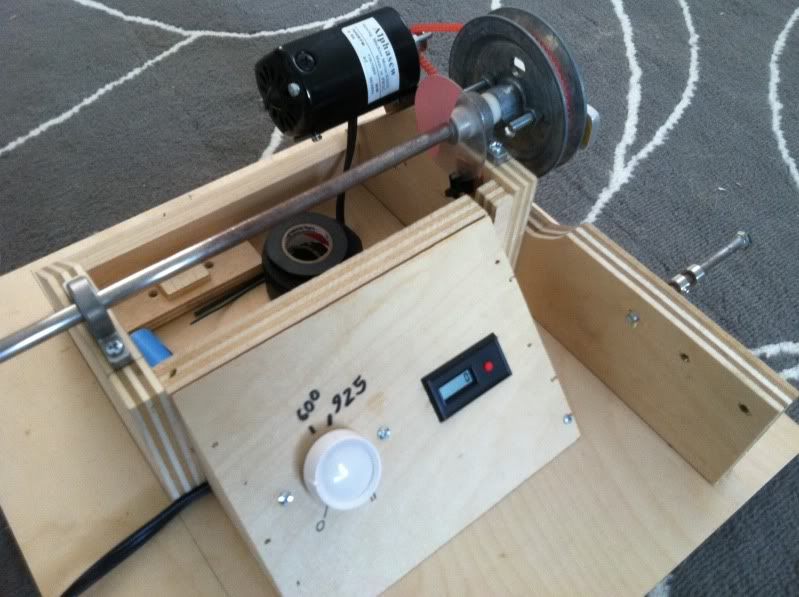

So... this is a little baffling? I went and tried to install a motor reverse switch today... and it doesn't work? I used a DPDT on-off-on in the standard motor reverse format (by that I mean an X between the 4 outter most lugs, motor sends on the two middle slugs, and the supply on two slugs at one end of the X). However... center-off works, but both on positions have the motor running CCW?! Something there doesn't seem right? Any thoughts? Can you not reverse a sewing machine motor? Can you not reverse a motor when running on AC? And if it is an AC current issue how in the work am I going to run something like a sewing machine motor off DC?!

Frustrated,

Chris

Frustrated,

Chris

Comment