I am about to build a new winder based on Jason Lollar's. I have most of the parts already and should be up and running once I can get it assembled. For a counter, I have come up with idea that I wanted to bounce off the members here first. Basically, it consists of a thin steel wire extending out from the bobbin faceplate. As the plate turns, the wire is dragged across two steel contacts, thus completing the circuit to the counter. Would this idea work? Here is a drawing to illustrate my idea. It's sort of like a reed switch, but without a magnet.

Ad Widget

Collapse

Announcement

Collapse

No announcement yet.

Counter Idea

Collapse

X

-

How about this counter? Do you think it might be a good choice regardless of the method for tripping? It's super cheap.

American Science & Surplus : Does This Count?Chris Monck

eguitarplans.com

Comment

-

For best results, stay away from anything mechanical. Most of the guys are using an optical / thru beam sensor or a proximity detector.

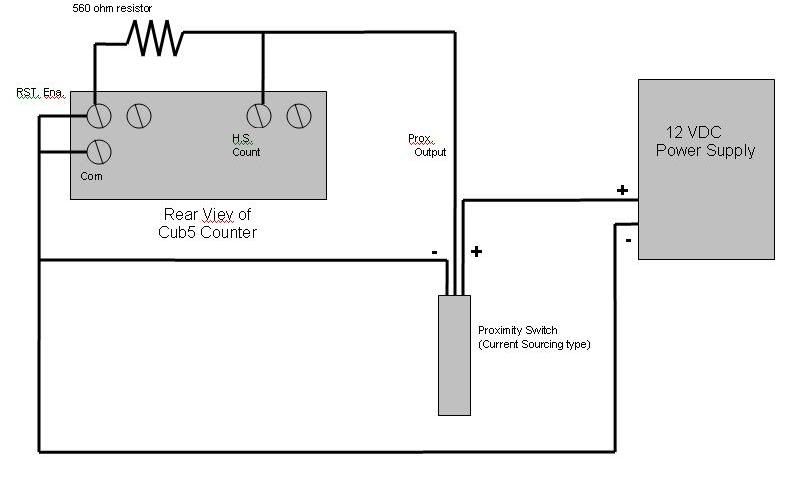

For me, I went the proximity detector route into a cub5 counter I found on Ebay. The problem I had was that the counter input circuit was too high an impedance for the prox detector to trigger it. My solution was to put a 560 ohm resistor across the output of the proximity detector. All is well, and my counter counts way faster than what I want to wind.

One of these days when I get a chance, I will draw up a schematic for posting here, as this problem periodocially pops up here.

Comment

-

Reed switch and magnet is pretty easy and cheap. You can use one of those "window security" type switches and get a small neo magnet, all for very cheap. I paid less than a buck for the switch at a surplus store and removed the magnet from discarded toy (Awww Dad!).

Comment

-

A reed switch an a magnet was my first attempt, and it didn't work for me. On my Cub5 counter there are two inputs, a high speed and a low speed.

On the high speed input the counter was actually counting the contact bouncing when the magnet came in contact. For example, I woould move the magnet close to the reed switch once, and it would register 5 counts.

So I used the "low speed" input, and the counter couldn't keep up with the speed of the winder.

Others may have better luck than I did with a magnetic reed switch, but the contact bounce on switch closure killed me.

Comment

-

If you're a hobby guy like me, using a bike odometer/speedometer is stupid simple, and takes about 5 minutes to hook up. Set it to wheel circumference = 1 meter and you get precision to within 10 turns, with no issues winding at the 600 RPM max of my setup. Spence had suggested this approach, and it works great for me.

Joe Gwinn posted about optimizing the reed switch approach, trick is, as David King mentioned upthread, getting the open/close cycle to be split 50/50 each rotation.

Comment

-

Boy, I'd really love a schematic. Even if it's just a rough sketch. I'm not fluent in electrical wiring so any help would be great. I've always thought a optical sensor would be the best approach, but I can't find a simple diagram on how to wire one up.Originally posted by MistaT View PostOne of these days when I get a chance, I will draw up a schematic for posting here, as this problem periodocially pops up here.Chris Monck

eguitarplans.com

Comment

-

Oh the bike odometer idea.. That's a good one!

Also in trying to get the reed switch thing to work, there was also the "duty cycle" issue, or open/close. Another problem I had, which has been alluded to earlier, is that the "on" signal needs to be long enough for everything to respond. In my case with the reed switch and magnet, the magnet would go past the switch too fast before the switch actually moved. (I think their "reaction time" if you will is 20 ms for a somewhat fast mechanical switch.)

I'm wondering about using the bike odometer (i'm guessing it has a magnet for the sensor??) how long its "on" time is?

I found on my setup that I needed my surface that the prox. detector was counting needed to be about an inch long. I also had to make the surface the same radius as it was rotating. I found that my set up was just catching the leading and trailing edge as it was spinning by the sensor (hope that makes sense..)

As far as a diagram.. Hopefully later today I will get a chance to draw something up.

Comment

-

You can get free samples of most optical sensors sent to your door from the manufacturer. Fairchild made the one I'm using (QRB1114) and it was dead simple to implement. It just needs a small DC voltage (1.8-2.2VDC @20 ma) to run the infrared led and a couple of leads from the detector back to the counter. I used aluminum foil as the reflector going 1/2 way around the back of my faceplate, the other half of the track was silicon carbide sandpaper, the black stuff, it absorbs and scatters the light really well so the photodetector shows a huge swing in resistance and the counter tracks that effortlessly. The only trick was to drop the DC supply voltage from the counter from 5V down to about 2V for the LED. I used on of the online led voltage drop calculators like this one:

The Best Current Limiting Resistor Calculator for Led's You need to know your supply voltage from the counter or it's power supply, (could be 3.3, 5, 9 or 12 VDC)

You need the voltage drop across the LED which for IR leds is usually about 1.65V (It will be listed in the sensor specs.) Lastly you input the current that the LED wants for it's supply. Most LEDs are happy drawing 20ma. Enter the data and it spits out the value of the resistor that you put in series between your supply and the led. In my case Vs=5V, Led Vdrop = 1.65V, I (current) = 20ma. The resistor needed was 180 Ohm.

Comment

-

This sounds very simple indeed. Couple of questions: What counter are you using? And, how wide is the track?Originally posted by David King View PostIt just needs a small DC voltage (1.8-2.2VDC @20 ma) to run the infrared led and a couple of leads from the detector back to the counter. I used aluminum foil as the reflector going 1/2 way around the back of my faceplate, the other half of the track was silicon carbide sandpaper, the black stuff, it absorbs and scatters the light really well so the photodetector shows a huge swing in resistance and the counter tracks that effortlessly.Chris Monck

eguitarplans.com

Comment

-

Fairchild recommends a track that's at least .2" wide.

My counter is an old Durrant 1800. It's got presets and relays so it stops the wind at the right number. It also has a DC bus voltage of 14V to run all the outboard contraptions. There are a bunch of tiny switches on the back to set all the parameters like count up/countdown, relay reset, high speed count vs low speed count. I picked up on ebay for $15 shipped, it probably cost $500 new in 1984. What I like best is the BIG LED display I can read from across the room. very handy that.

Comment

-

Would this work?Originally posted by David King View PostMy counter is an old Durrant 1800. It's got presets and relays so it stops the wind at the right number. It also has a DC bus voltage of 14V to run all the outboard contraptions. There are a bunch of tiny switches on the back to set all the parameters like count up/countdown, relay reset, high speed count vs low speed count. I picked up on ebay for $15 shipped, it probably cost $500 new in 1984. What I like best is the BIG LED display I can read from across the room. very handy that.

American Science & Surplus : Does This Count?Chris Monck

eguitarplans.com

Comment

-

It should work just fine and the price is right.

I tracked down a datasheet which is probably close enough:

http://www.redingtoncounters.com/lib...ry$0@492;EntryLast edited by David King; 02-08-2010, 10:11 PM.

Comment

-

Wiring diagram for a Cub5 counter

OK, sorry for the delay, but earlier I promised a wiring diagram on how I use a Cub5 counter with a proximity detector, so here it is:

Be aware there are two basic types of proximity switches, Current sinking and current sourcing. This diagram is for current sourcing.

Comment

Comment