Here's a video of my winder:

Vids :: Winder from wire to counter video by Bizzar_Guitars - Photobucket

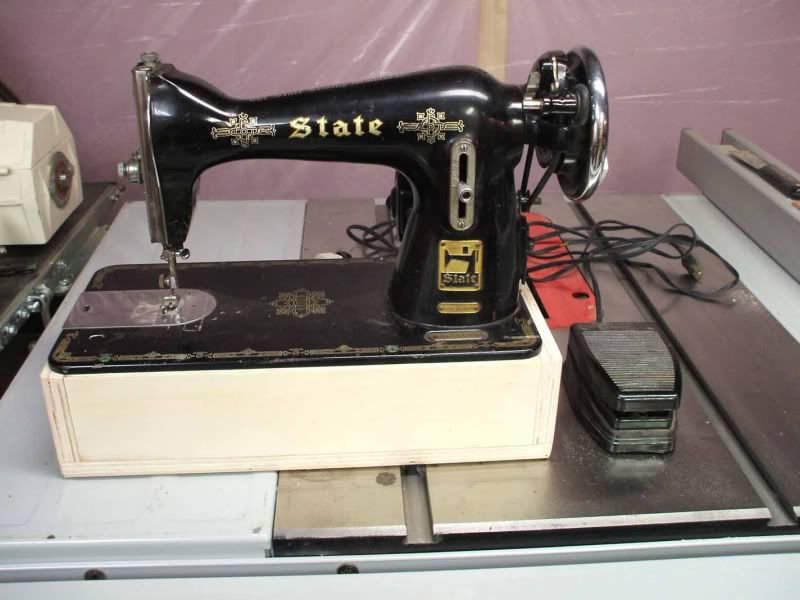

The wire comes off the spool (on the floor), passed through Kleenix in the jaws of a clothes pin (to act as a tensioner), into an arcing plastic tube (which also acts as a tensioner), to the traverse, then through a limiter loop (made to match the bobbin(s) being wound), and onto the bobbin (attached to the 'fly wheel' with double sided tape).

The traverse is driven by an internal gear in the sewing machine.

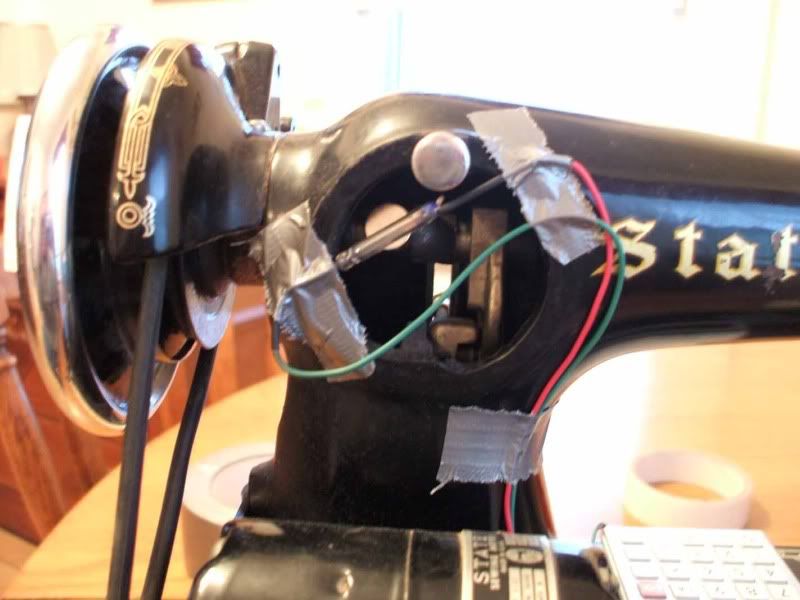

The counter is a reed switch triggered by a rare earth magnet on the gear.

The actual counter is The Wind Counter program.

The program gives you: (clockwise from top left) number of turns; turns per minute; number of turns; and estimated completion time.

It works for me.

Ciao,

Garth

Vids :: Winder from wire to counter video by Bizzar_Guitars - Photobucket

The wire comes off the spool (on the floor), passed through Kleenix in the jaws of a clothes pin (to act as a tensioner), into an arcing plastic tube (which also acts as a tensioner), to the traverse, then through a limiter loop (made to match the bobbin(s) being wound), and onto the bobbin (attached to the 'fly wheel' with double sided tape).

The traverse is driven by an internal gear in the sewing machine.

The counter is a reed switch triggered by a rare earth magnet on the gear.

The actual counter is The Wind Counter program.

The program gives you: (clockwise from top left) number of turns; turns per minute; number of turns; and estimated completion time.

It works for me.

Ciao,

Garth

Comment