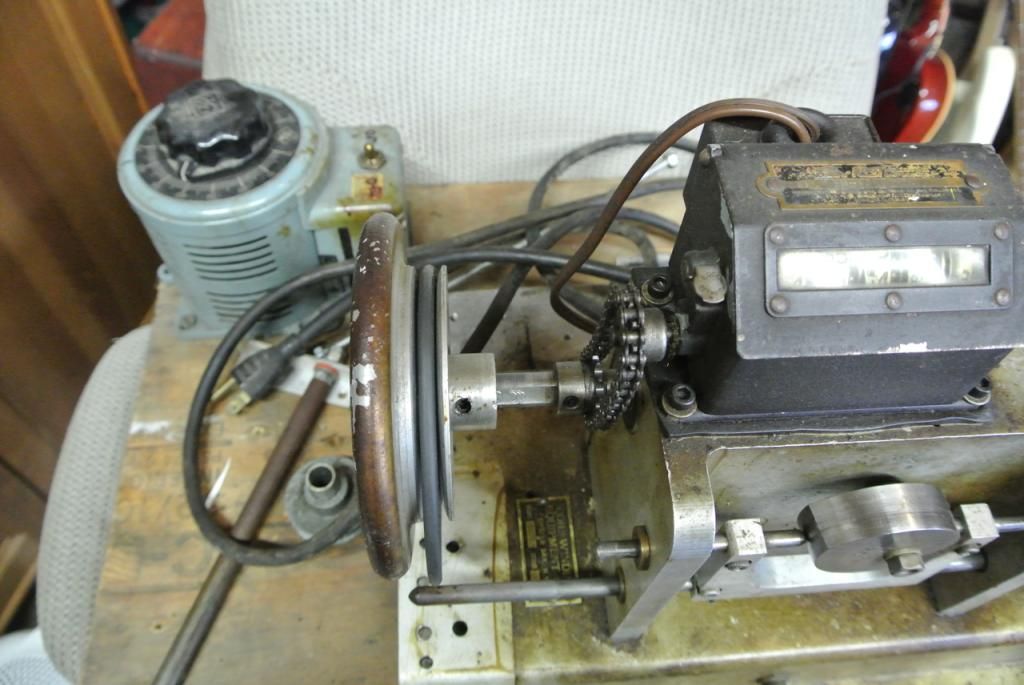

Hi, I've be meaning to post some photos of these. I've got a Coweco Moel C and a Model CS. I've been on the hunt for a few years for more or less "complete" mechanical auto traverse machines. I'm glad I took my time, did some research and asked questions. I like vintage guitars, pickups, electronics and the winding machines - particularly the machines use to wind those pickups.

I originally learned about these guys from all the photos of Abigail Ybarra hand winding Fender pickups on a COWECO CS. Then read about them here and found some literature online about them. Then asked a few knowledgeable people her for advice and I'm very grateful.

The gears and cams, as well as some other parts, are completely interchangeable between the 2 machines. They use adjustable cams, so one cam can do humbuckers & P90s as well as a bunch of Fender stuff. The intent is to do vintage correct Fender pickups on one of the same make and model machines they had during "the golden era."

Here's some photos:

more coming...

I originally learned about these guys from all the photos of Abigail Ybarra hand winding Fender pickups on a COWECO CS. Then read about them here and found some literature online about them. Then asked a few knowledgeable people her for advice and I'm very grateful.

The gears and cams, as well as some other parts, are completely interchangeable between the 2 machines. They use adjustable cams, so one cam can do humbuckers & P90s as well as a bunch of Fender stuff. The intent is to do vintage correct Fender pickups on one of the same make and model machines they had during "the golden era."

Here's some photos:

more coming...

Comment