Hey everyone just have a bit of a troubleshooting problem.

I've read this article: http://geek.scorpiorising.ca/windingtransformers.html

on rewinding old transformers and I'm attempting to do so. in the article it mentions taking the transformers out of microwaves for example and using them to make transformers for guitar amps after rewinding them. The first step really is to measure the transformer so you can figure out the turn ratio but i'm running into problems already. I have two different transformers from two microwaves i took apart and I can't get anything from either of them.

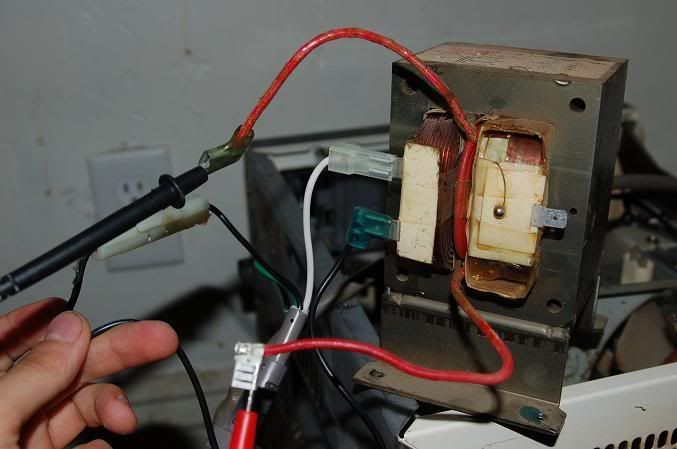

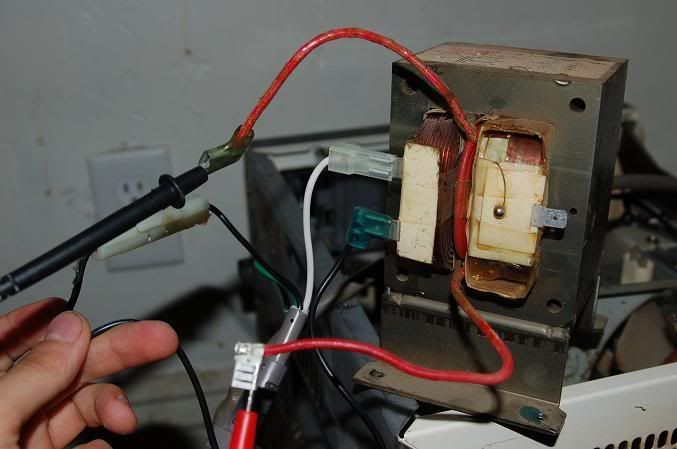

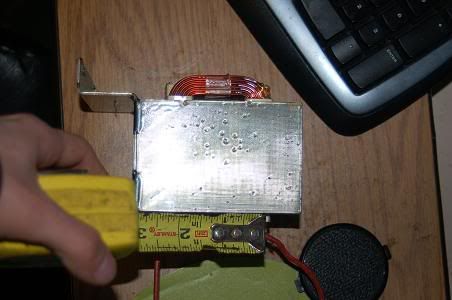

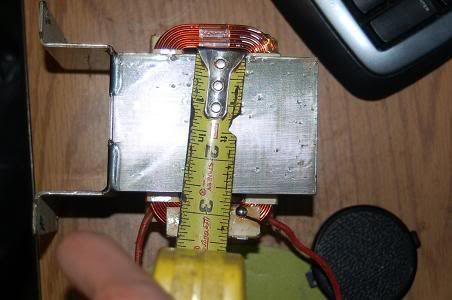

Here's what happened (pictures below): I connected the primary to the mains, left the ground wire unattached, connected one side of the secondary to my meter, then pluged the mains cable into the wall at which point I could here a humming noise comming from within the walls seemingly (this was much louder on the smaller transformer that was in better condition). I then connected the other side of the secondary to my other probe and.... nothing? the meter just read 0. here are the pics of the setup and of my meter. Also the last pic is of the sides of the transformer which have welds all along the laminations which seems kinda strange to me, isn't the point of having laminations that they aren't connected? I planned to grind the welds off with a dremel tool. let me know if this is a crazy idea haha

haha

I've read this article: http://geek.scorpiorising.ca/windingtransformers.html

on rewinding old transformers and I'm attempting to do so. in the article it mentions taking the transformers out of microwaves for example and using them to make transformers for guitar amps after rewinding them. The first step really is to measure the transformer so you can figure out the turn ratio but i'm running into problems already. I have two different transformers from two microwaves i took apart and I can't get anything from either of them.

Here's what happened (pictures below): I connected the primary to the mains, left the ground wire unattached, connected one side of the secondary to my meter, then pluged the mains cable into the wall at which point I could here a humming noise comming from within the walls seemingly (this was much louder on the smaller transformer that was in better condition). I then connected the other side of the secondary to my other probe and.... nothing? the meter just read 0. here are the pics of the setup and of my meter. Also the last pic is of the sides of the transformer which have welds all along the laminations which seems kinda strange to me, isn't the point of having laminations that they aren't connected? I planned to grind the welds off with a dremel tool. let me know if this is a crazy idea

haha

haha

Comment