Related topic: Do you know when to throw up your hands and declare the patient deceased?

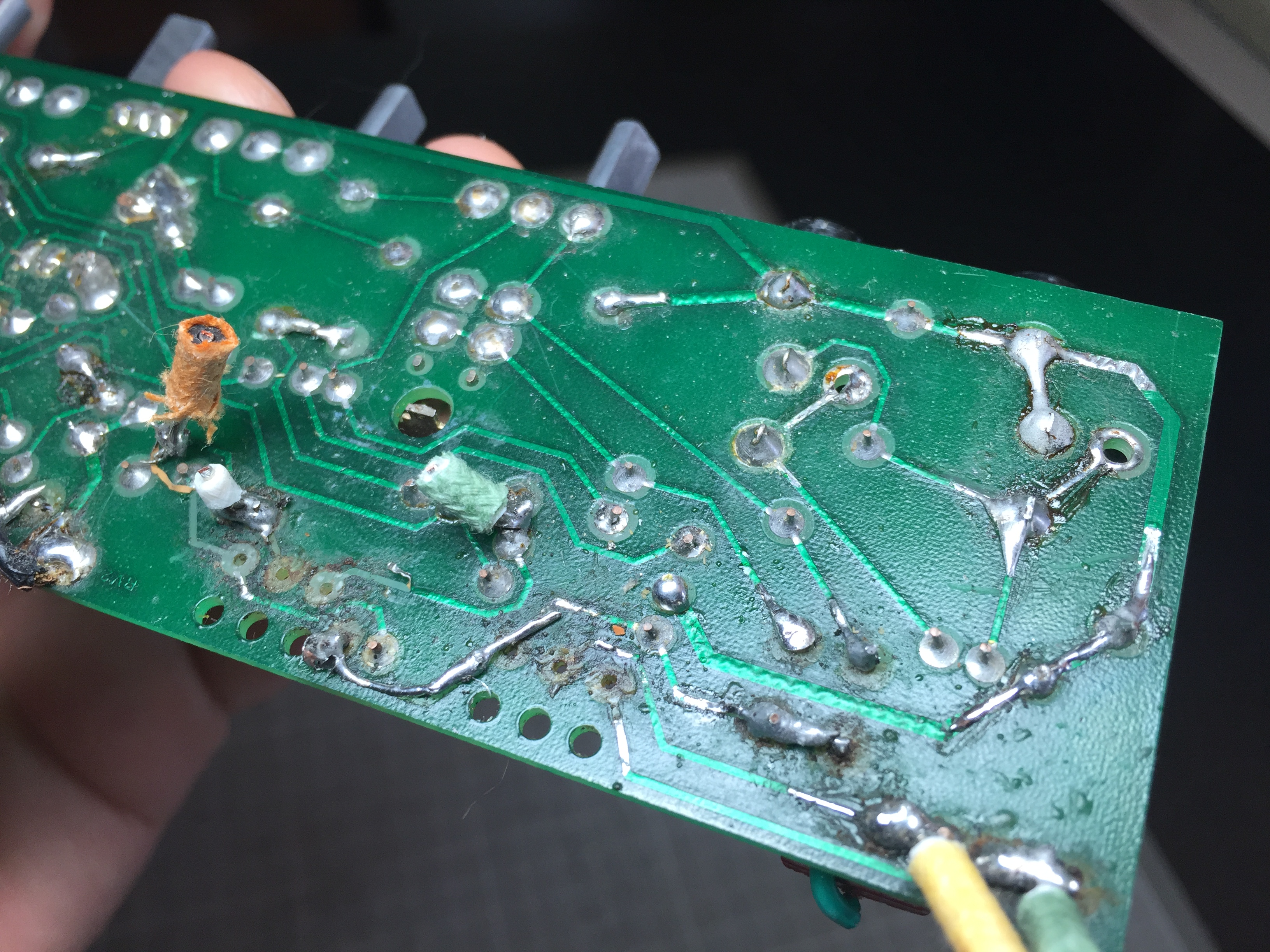

I counted twenty or more lifted traces on this Champ 12:

I counted twenty or more lifted traces on this Champ 12:

Indeed, as long as the electrical connection is stable and reliable long term as any other method I just don't see any problem with some splicing when it's practical or sometimes clearly the less detrimental option.

Indeed, as long as the electrical connection is stable and reliable long term as any other method I just don't see any problem with some splicing when it's practical or sometimes clearly the less detrimental option.

Comment