Hi ken moon, *thanks* for posting.

Just hope the trenchcoat and hat guys don't send you to Guantanamo on a one way ticket.

Love to see "the real deal" with my own eyes.

As usual, "real life" is much more solid and to the point than imagination.

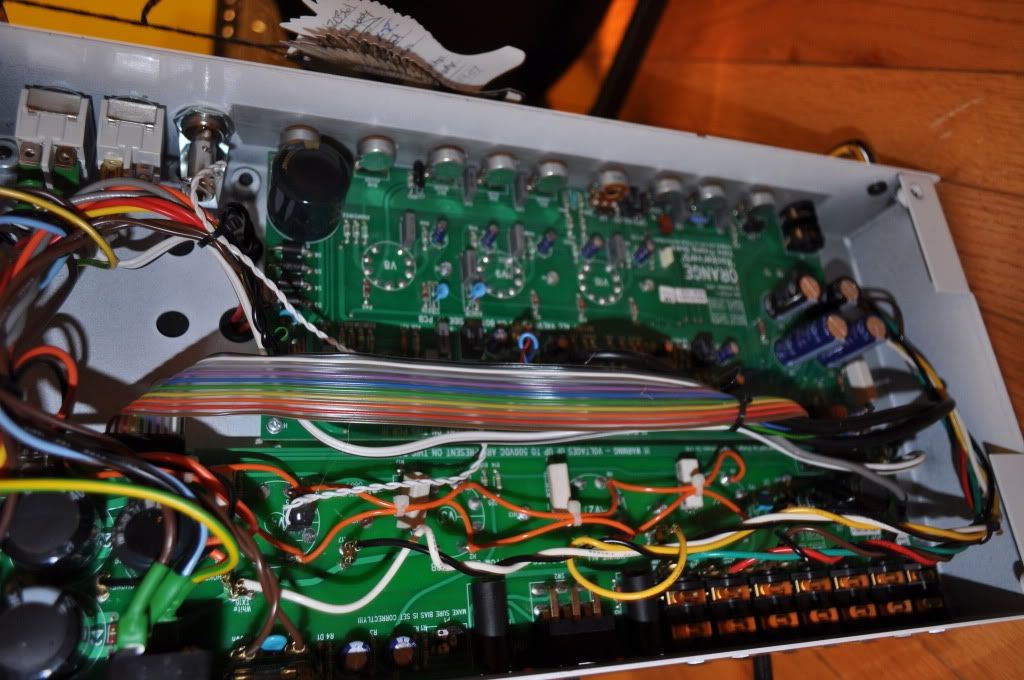

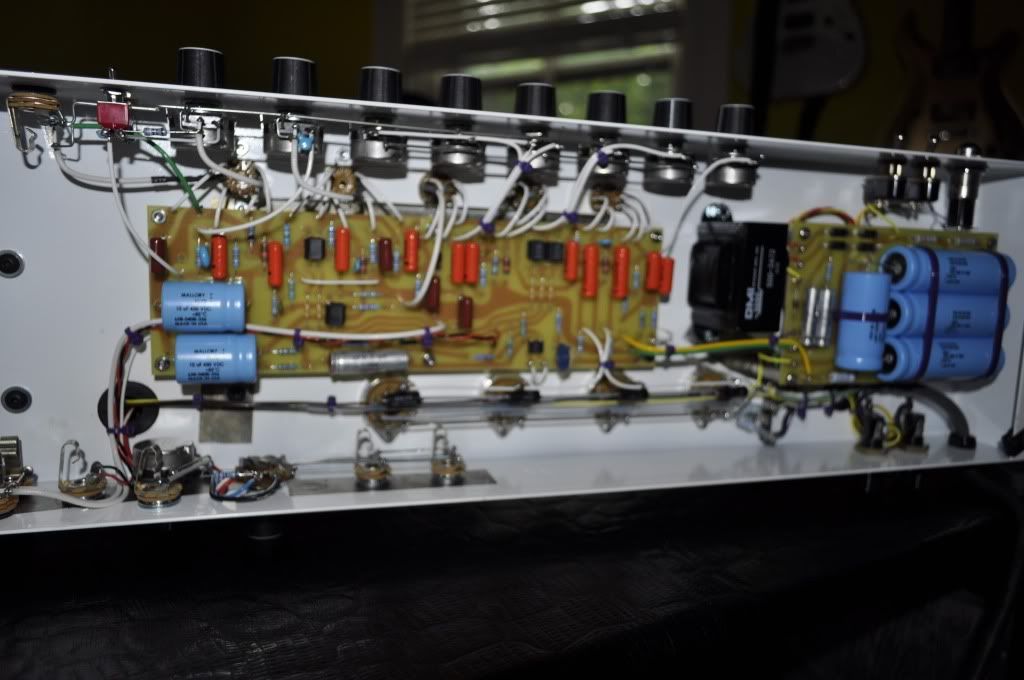

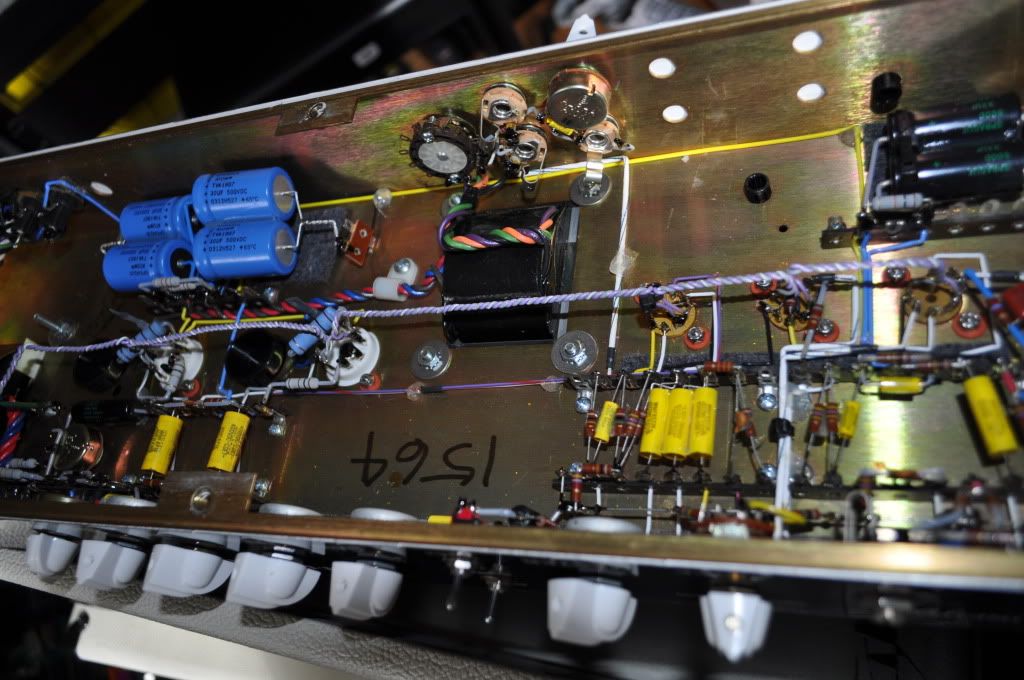

What amazes me most is that these PCBs are so close to a normal, well made commercial/industrial product.

No gamma ray generators, plutonium bars or Moon rocks here.

Yes, I'm sure they were made with with the best, deeply tested (no random sampling here) and of course, must have cost more than a similar commercial product .... but they are not "something else" , if you know what I mean.

PS: don't want to know what they exactly are or do, just looking at them was enough.

Thanks again.

Just hope the trenchcoat and hat guys don't send you to Guantanamo on a one way ticket.

Love to see "the real deal" with my own eyes.

As usual, "real life" is much more solid and to the point than imagination.

What amazes me most is that these PCBs are so close to a normal, well made commercial/industrial product.

No gamma ray generators, plutonium bars or Moon rocks here.

Yes, I'm sure they were made with with the best, deeply tested (no random sampling here) and of course, must have cost more than a similar commercial product .... but they are not "something else" , if you know what I mean.

PS: don't want to know what they exactly are or do, just looking at them was enough.

Thanks again.

Comment