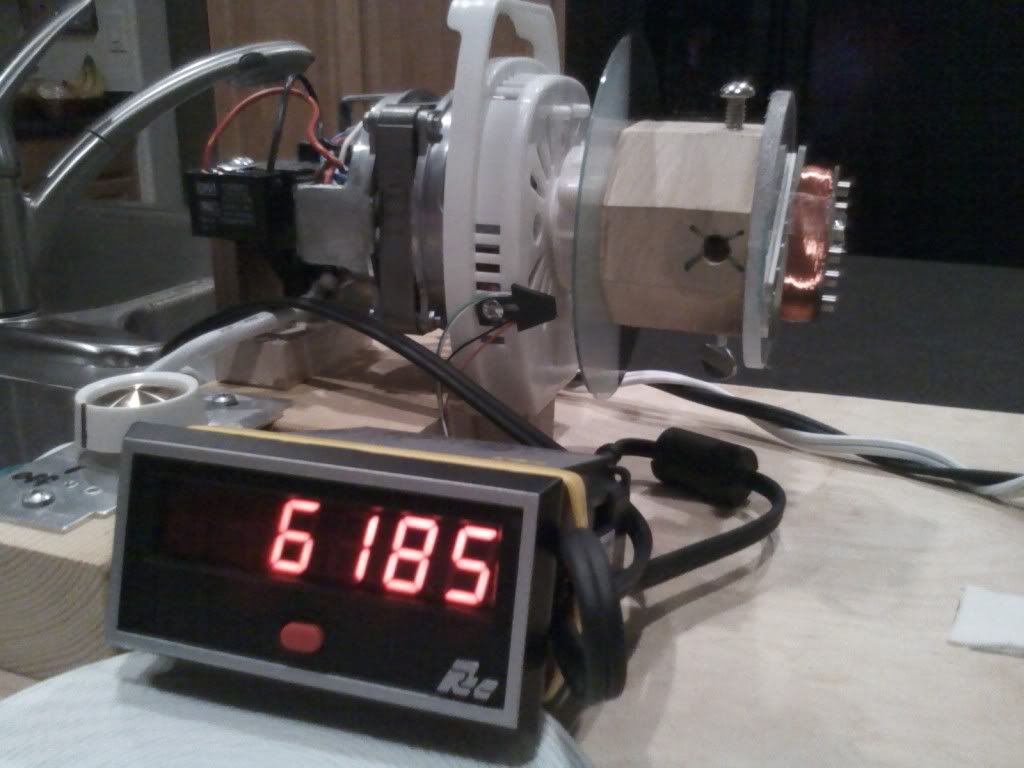

got my winder up and running with a huge THANK YOU to everyone on this forum who helped me in one way or another..

i've wound my first coil in the picture, but i'm noticing that my coil is relatively 'loose' the windings move easy when touched and the coil is probably larger then it should be for how many winds on it.. any winding tips you guys can provide would be appreciated! I'm not asking for any of your personal trade secrets or anything just some pointers that would be helpful for a nice neat coil (and i realize alot of this is going to just have to come with practice and time, like anything else..).

thanks again to everyone here for helping me along this far!

Comment